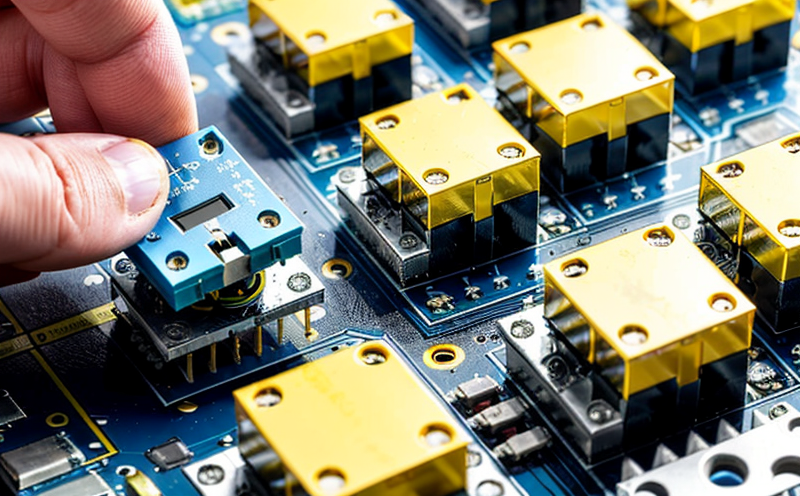

Testing the protection mechanisms in place to ensure safe operation of electrical circuits in devices

Ensuring Electrical Safety Why Testing Protection Mechanisms in Devices Matters

In todays fast-paced world, businesses rely heavily on electrical devices to keep operations running smoothly. From industrial equipment to household appliances, these devices are an integral part of modern life. However, with great power comes great responsibility and a significant risk of electrical shock, fire, or other hazards if not properly designed or maintained.

Thats where Eurolab comes in. Our laboratory services specialize in testing the protection mechanisms in place to ensure safe operation of electrical circuits in devices. This critical process ensures that your business is complying with industry standards and regulations, while also minimizing the risk of accidents and downtime.

The Importance of Testing Protection Mechanisms

In an increasingly complex world, its easy to overlook the importance of safety features in electrical devices. However, neglecting these crucial mechanisms can have devastating consequences. A single electrical shock or malfunction can lead to costly repairs, lost productivity, and even litigation. By investing in protection mechanism testing, businesses like yours can

Prevent electrical shocks and fires Testing ensures that devices meet strict safety standards, reducing the risk of accidents and property damage.

Comply with industry regulations Regular testing helps ensure compliance with relevant standards, codes, and regulations, minimizing the likelihood of fines or penalties.

Minimize downtime and costs Identifying potential issues early on allows for proactive maintenance, reducing the risk of equipment failure and costly repairs.

Protect your brand reputation Demonstrating a commitment to safety through regular testing can boost customer trust and confidence in your products.

Key Benefits of Using Eurolabs Services

Our laboratory services offer a range of benefits that go beyond mere compliance. By choosing Eurolab, youll enjoy

Comprehensive testing Our expert technicians conduct thorough examinations of electrical devices, identifying potential risks and vulnerabilities.

Customized solutions We work closely with clients to develop tailored testing programs that meet specific business needs.

Rapid turnaround times Our state-of-the-art facilities enable fast and efficient testing, minimizing downtime and ensuring timely delivery of results.

Expert analysis and reporting Detailed reports provide actionable insights, allowing businesses to implement corrective measures and maintain a safe working environment.

Additional Benefits

In addition to the above advantages, our services also offer

Improved product quality Regular testing helps manufacturers identify design flaws or manufacturing defects, leading to enhanced product reliability.

Enhanced customer satisfaction By demonstrating a commitment to safety, businesses can build trust with customers and maintain a strong reputation in the market.

Increased efficiency Identifying potential issues early on allows for proactive maintenance, reducing downtime and optimizing resource allocation.

Frequently Asked Questions

Q What types of devices do you test?

A Our laboratory services cover a wide range of electrical devices, including industrial equipment, household appliances, medical devices, and more.

Q How often should I schedule testing?

A The frequency of testing depends on various factors, such as device usage, industry regulations, and specific business requirements. Well work with you to develop a customized testing program.

Q What kind of reporting can I expect?

A Our expert technicians provide detailed reports highlighting potential risks, vulnerabilities, and areas for improvement. These insights enable businesses to implement corrective measures and maintain a safe working environment.

Q Can I trust the results?

A Absolutely! Our laboratory services adhere to industry-recognized standards and regulations, ensuring accurate and reliable testing results.

Conclusion

In conclusion, Testing the protection mechanisms in place to ensure safe operation of electrical circuits in devices is a critical process that can make all the difference for businesses. By partnering with Eurolab, youll not only comply with industry regulations but also enjoy a range of benefits that go beyond mere compliance. Dont wait until its too late schedule your testing program today and safeguard your business against electrical hazards.

Why Choose Eurolab?

Our laboratory services are designed to meet the unique needs of businesses like yours. With our expert technicians, state-of-the-art facilities, and commitment to quality, you can trust us to deliver accurate and reliable results. Dont just take our word for it choose Eurolab for all your protection mechanism testing needs.

Get Started Today

Dont miss out on this opportunity to safeguard your business against electrical hazards. Contact us to schedule your testing program and take the first step towards a safer working environment.

-

Evaluating the electrical safety of consumer products to prevent shock, short circuits, or fires

-

Testing the insulation and grounding of electrical components in household appliances and electronics

-

Verifying the compliance of electrical products with safety standards to prevent electric hazards

-

Simulating electrical faults or failures to assess the risk of electrical shock or fire in consumer products

-

Assessing the effectiveness of circuit breakers, fuses, or other safety devices in electrical products

-

Simulating accidental electrical surges or power failures to test the resilience of devices

-

Testing the resistance of electrical wiring and components to wear and degradation over time

-

Evaluating the safe handling of electrical products, including exposed wires or connections

-

Testing for the durability and safety of electrical connectors, plugs, and sockets used in consumer products

-

Ensuring that products have proper earthing and insulation to protect users from electric shock

-

Verifying that electrical appliances are free from harmful electromagnetic interference (EMI) or electromagnetic fields (EMF)

-

Testing the performance of safety features like thermal fuses or automatic shut-off systems in electrical products

-

Assessing electrical safety in battery-powered consumer goods to ensure they do not overheat or cause fires

-

Testing the integrity of electrical shielding or covers to prevent accidental contact with live parts

-

Verifying that products comply with global electrical safety certifications and standards

-

Assessing the durability of electrical components under conditions such as humidity, heat, or vibration

-

Simulating long-term usage to test the reliability of electrical systems in consumer devices

-

Testing the protection of user interfaces like buttons or screens from electrical risks

-

Evaluating the safety of electrical power supplies used in consumer goods like kitchen appliances or power tools

-

Ensuring that electrical systems in products are adequately tested for shock, fire, and overload protection