Testing the performance of safety features like thermal fuses or automatic shut-off systems in electrical products

Unlocking Safety and Compliance Testing the Performance of Safety Features in Electrical Products

In todays fast-paced world, electrical products have become an integral part of our daily lives. From smartphones to household appliances, these devices are designed to make our lives easier, more convenient, and connected. However, with increasing complexity and power consumption, there is also a growing risk of electrical accidents, injuries, and even fatalities.

Thats where Testing the performance of safety features like thermal fuses or automatic shut-off systems in electrical products comes into play a critical laboratory service provided by Eurolab that ensures your electrical products meet the highest standards of safety and compliance. In this article, we will delve into the importance of testing safety features, the benefits of using our services, and provide answers to frequently asked questions.

What is Testing the Performance of Safety Features?

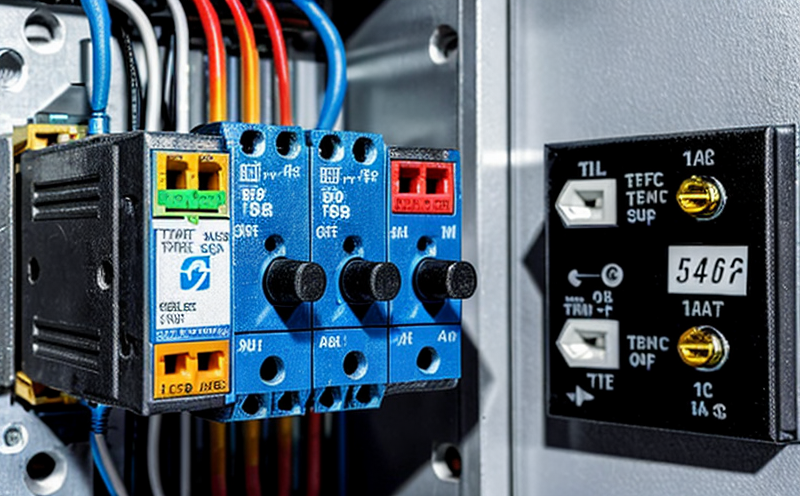

Testing the performance of safety features like thermal fuses or automatic shut-off systems in electrical products involves a series of rigorous laboratory tests designed to assess the efficacy of these critical components. These components are crucial in preventing electrical accidents by detecting overheating, overloading, or other hazardous conditions and automatically shutting off the power supply.

Our laboratory services focus on evaluating the performance of thermal fuses, automatic shut-off systems, and other safety features that protect users from electrical hazards. Our experienced team of engineers and technicians utilize state-of-the-art equipment to simulate real-world scenarios, pushing your products to their limits.

Why is Testing the Performance of Safety Features Essential for Businesses?

In todays competitive market, businesses must adhere to stringent regulations and industry standards to ensure customer safety and trust. Failure to comply with these requirements can result in costly recalls, damaged reputations, and even regulatory fines.

Here are some compelling reasons why testing the performance of safety features is essential for businesses

Advantages of Using Eurolabs Services

Enhanced Safety Our rigorous testing protocols ensure that your electrical products meet or exceed international standards for safety.

Compliance Assurance We help you navigate complex regulations and industry standards, giving you peace of mind and reducing the risk of non-compliance.

Cost Savings Identifying potential issues early on can save you from costly recalls, product redesigns, and legal fees.

Increased Efficiency Our streamlined testing process ensures that your products are ready for market in a timely manner, minimizing production delays.

Heres a breakdown of the key benefits

Key Benefits

Reduced risk of electrical accidents

Enhanced customer trust and loyalty

Improved brand reputation

Compliance with international standards and regulations

Cost savings through early issue detection

Increased efficiency in product development

QA Frequently Asked Questions

What types of products can be tested for safety features?

Our laboratory services cater to a wide range of electrical products, including household appliances, industrial equipment, medical devices, and more.

How do you test thermal fuses or automatic shut-off systems?

We utilize advanced testing equipment to simulate real-world scenarios, pushing your products to their limits. Our team then evaluates the performance of safety features in response to these conditions.

What are the benefits of testing safety features in-house versus outsourcing to Eurolab?

Outsourcing to a reputable laboratory like Eurolab ensures that you receive unbiased, expert testing and analysis. This eliminates potential conflicts of interest and ensures that your products meet the highest standards of safety and compliance.

Conclusion

In todays highly competitive market, businesses must prioritize customer safety and compliance above all else. By leveraging Eurolabs expertise in testing the performance of safety features like thermal fuses or automatic shut-off systems in electrical products, you can unlock a safer, more efficient, and more compliant product development process.

Dont risk your reputation and customer trust choose Eurolab for peace of mind and assurance that your electrical products meet the highest standards of safety and compliance.

-

Evaluating the electrical safety of consumer products to prevent shock, short circuits, or fires

-

Testing the insulation and grounding of electrical components in household appliances and electronics

-

Verifying the compliance of electrical products with safety standards to prevent electric hazards

-

Simulating electrical faults or failures to assess the risk of electrical shock or fire in consumer products

-

Testing the protection mechanisms in place to ensure safe operation of electrical circuits in devices

-

Assessing the effectiveness of circuit breakers, fuses, or other safety devices in electrical products

-

Simulating accidental electrical surges or power failures to test the resilience of devices

-

Testing the resistance of electrical wiring and components to wear and degradation over time

-

Evaluating the safe handling of electrical products, including exposed wires or connections

-

Testing for the durability and safety of electrical connectors, plugs, and sockets used in consumer products

-

Ensuring that products have proper earthing and insulation to protect users from electric shock

-

Verifying that electrical appliances are free from harmful electromagnetic interference (EMI) or electromagnetic fields (EMF)

-

Assessing electrical safety in battery-powered consumer goods to ensure they do not overheat or cause fires

-

Testing the integrity of electrical shielding or covers to prevent accidental contact with live parts

-

Verifying that products comply with global electrical safety certifications and standards

-

Assessing the durability of electrical components under conditions such as humidity, heat, or vibration

-

Simulating long-term usage to test the reliability of electrical systems in consumer devices

-

Testing the protection of user interfaces like buttons or screens from electrical risks

-

Evaluating the safety of electrical power supplies used in consumer goods like kitchen appliances or power tools

-

Ensuring that electrical systems in products are adequately tested for shock, fire, and overload protection