Measurement of Brinell hardness for metals

The Importance of Accurate Metal Hardness Testing Understanding Brinell Hardness Measurement

As a business owner in the metal industry, you understand the significance of ensuring that your products meet specific standards and requirements. One critical aspect of metal production is determining the hardness of metals, which directly impacts their performance, durability, and overall quality. In this article, we will delve into the world of Brinell hardness measurement, a laboratory service offered by Eurolab, and explore its importance for businesses.

What is Brinell Hardness Measurement?

Brinell hardness testing is a widely accepted method used to determine the hardness of metals. It involves measuring the diameter of the indentation created on the metal surface when a specific load is applied using a hardened steel ball. This measurement is then compared to a standard scale, which provides a numerical value representing the materials hardness.

Why Choose Brinell Hardness Measurement?

At Eurolab, we have years of experience providing accurate and reliable Brinell hardness measurements for various industries. Our experts understand that each metal type requires specific testing procedures, and we are committed to delivering precise results that meet your business needs.

Here are the key benefits of using Brinell hardness measurement

Accurate Material Selection With precise hardness values, you can select the most suitable materials for your products, ensuring optimal performance and longevity.

Improved Quality Control Regular Brinell hardness testing helps identify potential material defects or variations, enabling you to take corrective actions before they impact your business.

Enhanced Product Reliability By understanding your materials hardness levels, you can design and manufacture products that meet specific requirements, reducing the risk of failure or damage.

Compliance with Industry Standards Brinell hardness testing is widely accepted by regulatory bodies and industry standards organizations, ensuring compliance with relevant regulations.

Cost Savings Accurate material selection and quality control can lead to significant cost savings by minimizing waste, rework, and potential liability claims.

How Does Eurolab Ensure the Quality of Its Services?

At Eurolab, we take pride in our commitment to excellence. Here are some measures we have implemented to ensure the accuracy and reliability of our Brinell hardness measurements

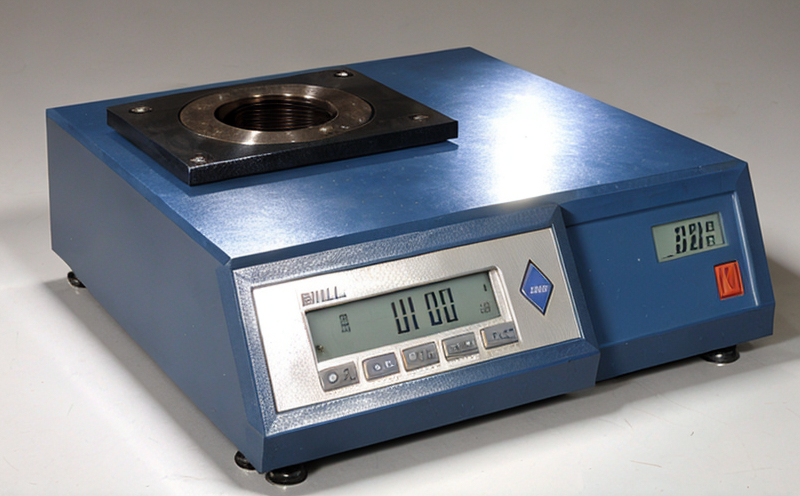

State-of-the-Art Equipment Our laboratory is equipped with advanced testing equipment that meets or exceeds industry standards.

Trained and Experienced Staff Our technicians undergo regular training and have extensive experience in performing Brinell hardness tests on various metal types.

Rigorous Quality Control Procedures We maintain a strict quality control process to ensure accuracy, precision, and reliability of our test results.

QA Frequently Asked Questions About Brinell Hardness Measurement

Q1 What is the purpose of Brinell hardness testing?

A1 Brinell hardness testing determines the hardness of metals by measuring the diameter of the indentation created on the metal surface when a specific load is applied using a hardened steel ball.

Q2 Which industries benefit from Brinell hardness measurement?

A2 Various industries, including construction, automotive, aerospace, and manufacturing, rely on accurate Brinell hardness measurements to ensure material quality and performance.

Q3 How does Eurolab ensure the accuracy of its test results?

A3 Our laboratory follows rigorous quality control procedures, employs trained technicians with extensive experience, and uses state-of-the-art testing equipment to ensure precision and reliability.

Conclusion

In conclusion, Brinell hardness measurement is a vital service for businesses involved in metal production. By understanding the advantages of this laboratory service and selecting a reputable provider like Eurolab, you can ensure accurate material selection, improved quality control, enhanced product reliability, compliance with industry standards, and cost savings.