Hardness testing for high-temperature alloys

The Crucial Role of Hardness Testing for High-Temperature Alloys Ensuring Material Integrity and Performance

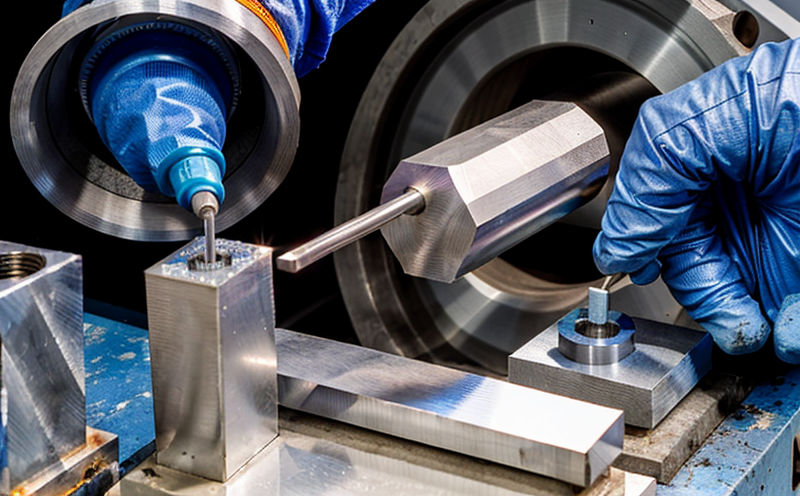

In todays fast-paced industrial landscape, materials science plays a pivotal role in driving innovation and efficiency across various sectors. Among the numerous testing methods available, hardness testing stands out as an indispensable tool for evaluating high-temperature alloys properties. These exceptional materials are designed to withstand extreme temperatures, making them ideal for applications ranging from aerospace engineering to power generation.

At Eurolab, we recognize the significance of accurate hardness testing in ensuring material integrity and performance. Our laboratory service is equipped with cutting-edge technology and staffed by experienced experts who deliver precise results with unparalleled efficiency.

What is Hardness Testing for High-Temperature Alloys?

Hardness testing involves measuring a materials resistance to deformation under various conditions, typically expressed as a numerical value known as the hardness number (H). This measure serves as an indicator of a materials overall strength and ability to withstand wear and tear. In the case of high-temperature alloys, such as those made from nickel-chromium or cobalt-based materials, hardness testing is crucial for determining their behavior under thermal stress.

High-temperature alloys are engineered to perform optimally in environments with extreme temperatures, often beyond 1000C (1832F). Their excellent strength and resistance to creep make them ideal for applications like heat exchangers, turbines, and high-performance coatings. However, their unique properties also present challenges when it comes to testing and characterization.

Why is Hardness Testing Essential for High-Temperature Alloys?

Hardness testing provides a wealth of information about a materials microstructure, composition, and mechanical behavior under various conditions. For high-temperature alloys, this data is particularly valuable due to the following key benefits

Predictive Maintenance By assessing hardness levels, manufacturers can anticipate potential issues related to thermal stress, allowing for proactive maintenance and reducing downtime.

Quality Control Accurate hardness testing ensures that materials meet specified requirements, guaranteeing consistency and reliability in production processes.

Material Selection Understanding a materials hardness properties enables engineers to select the most suitable alloy for specific applications, optimizing performance and lifespan.

Process Optimization Hardness testing informs process optimization strategies, helping manufacturers to refine their procedures and improve overall efficiency.

Advantages of Using Hardness Testing for High-Temperature Alloys

Eurolabs expertise in hardness testing offers numerous advantages when working with high-temperature alloys. Some key benefits include

Reliable Results Our state-of-the-art equipment and experienced technicians ensure precise measurements, eliminating the risk of inaccurate or misleading data.

Comprehensive Analysis We provide detailed reports that encompass not only hardness levels but also microstructural analysis, allowing for a comprehensive understanding of material behavior.

Fast Turnaround Times Our streamlined process ensures quick turnaround times without compromising on quality, enabling businesses to make informed decisions and stay ahead of the competition.

Flexible Sampling Options We accommodate various sampling types, from small samples to large quantities, catering to diverse client needs.

QA Hardness Testing for High-Temperature Alloys

What is the purpose of hardness testing high-temperature alloys?

To assess material properties, predict potential issues, and optimize processes.

How does Eurolab ensure accurate results?

Through state-of-the-art equipment and experienced technicians.

Can hardness testing provide information about a materials microstructure?

Yes, detailed reports include microstructural analysis for comprehensive understanding.

What types of sampling are supported by Eurolabs hardness testing service?

Various sampling types, including small samples and large quantities.

By partnering with Eurolab, businesses can rest assured that their high-temperature alloys are subject to rigorous testing, ensuring optimal performance, longevity, and reliability in demanding applications. Dont compromise on material integrity choose the best laboratory service for your needs.