Ultrasonic testing for weld integrity

Ensuring Weld Integrity with Ultrasonic Testing A Crucial Laboratory Service for Businesses

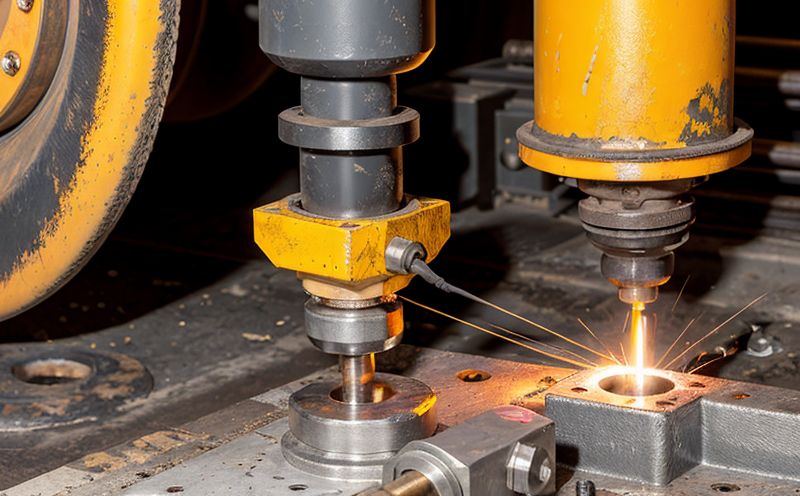

In the world of industrial manufacturing and construction, weld integrity is a critical factor that determines the overall safety and reliability of a structure or equipment. A weak or flawed weld can lead to catastrophic consequences, including accidents, injuries, and costly repairs. To mitigate these risks, businesses rely on advanced testing methods to assess the quality and integrity of their welds. One such method is Ultrasonic testing for weld integrity, a laboratory service offered by Eurolab that has revolutionized the way industries ensure the reliability of their welded components.

What is Ultrasonic Testing for Weld Integrity?

Ultrasonic testing (UT) is a non-destructive examination technique used to inspect the internal structure and quality of materials, including welds. This method involves using high-frequency sound waves to detect any flaws or defects within a material. When it comes to weld integrity, UT provides an accurate assessment of the welding process, identifying potential issues that may compromise the structural integrity of the component.

The Importance of Weld Integrity Testing

Weld integrity is crucial for businesses operating in various industries, including

Oil and gas

Aerospace

Automotive

Construction

Power generation

A weakened or flawed weld can lead to

Equipment failure

Safety hazards

Reduced product lifespan

Increased maintenance costs

Environmental risks

Advantages of Using Ultrasonic Testing for Weld Integrity

Eurolabs ultrasonic testing service offers numerous benefits, including

Key Benefits

Accuracy UT provides a precise assessment of weld integrity, reducing the risk of false positives or negatives.

Speed The process is relatively quick, allowing businesses to save time and resources.

Cost-effectiveness By identifying potential issues early on, businesses can avoid costly repairs and replacements.

Non-destructive UT does not damage the material being tested, making it an ideal method for assessing weld integrity without compromising the components functionality.

Reliability Our expert technicians ensure that all testing procedures are followed to the letter, guaranteeing reliable results.

How Does Ultrasonic Testing Work?

The ultrasonic testing process involves several steps

Preparation The component is thoroughly cleaned and prepared for testing.

Calibration The UT equipment is calibrated to ensure accurate readings.

Testing High-frequency sound waves are directed at the weld, generating echoes that indicate any internal defects or flaws.

Interpretation Our expert technicians analyze the test results, identifying potential issues and providing a detailed report.

Common Applications of Ultrasonic Testing for Weld Integrity

Eurolabs ultrasonic testing service is suitable for a wide range of applications, including

Weld inspection UT is used to assess the quality and integrity of welds in various materials, such as steel, aluminum, and titanium.

Material characterization Our service helps businesses determine the material properties, ensuring that components meet specified requirements.

Quality control Regular ultrasonic testing ensures that products adhere to industry standards and regulatory requirements.

QA Frequently Asked Questions

Q What types of materials can be tested using ultrasonic testing for weld integrity?

A Our service is suitable for various materials, including steel, aluminum, titanium, and other alloys.

Q How long does the ultrasonic testing process typically take?

A The duration of the test depends on the components size and complexity. On average, it takes between 1-5 hours to complete a UT examination.

Q Is ultrasonic testing non-destructive?

A Yes, our service is non-destructive, meaning that the material being tested remains intact and functional after the procedure.

Q What are the advantages of using Eurolabs ultrasonic testing service over other methods?

A Our expert technicians, state-of-the-art equipment, and thorough reporting ensure accurate and reliable results. Additionally, our service is cost-effective and time-efficient.

Conclusion

In conclusion, Ultrasonic testing for weld integrity is a crucial laboratory service provided by Eurolab that helps businesses ensure the reliability of their welded components. With numerous advantages, including accuracy, speed, and non-destructive capabilities, this method has revolutionized the way industries assess weld quality. By partnering with Eurolab, companies can reduce the risk of equipment failure, safety hazards, and environmental risks, ultimately saving time, resources, and money.

Get in Touch

To learn more about Eurolabs ultrasonic testing service for weld integrity or to schedule a test, please visit our website at website URL. Our expert technicians are available to answer any questions you may have and provide a detailed report of the testing procedure.