Thermal testing of materials used in automotive engines for high-temperature performance

The Unyielding Quest for High-Temperature Performance Why Thermal Testing of Materials is a Game-Changer for Automotive Engines

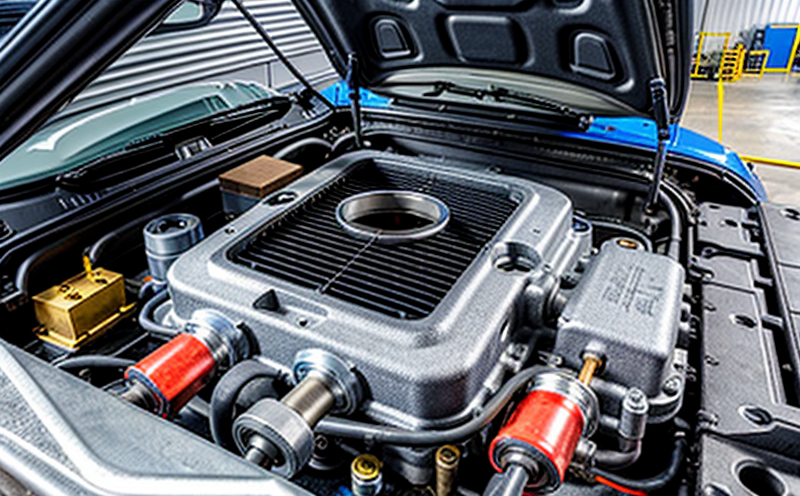

In the high-stakes world of automotive engineering, one key factor can make all the difference between success and failure high-temperature performance. As engines continue to evolve with advanced technologies and increasingly demanding applications, manufacturers are under pressure to ensure that their materials can withstand the extreme temperatures generated during operation. This is where thermal testing comes in a critical laboratory service that evaluates the ability of materials to maintain structural integrity and performance in scorching conditions.

At Eurolab, weve spent years perfecting our thermal testing capabilities, enabling clients to push the boundaries of whats possible in automotive engineering. By leveraging cutting-edge technology and expert knowledge, we provide businesses with a crucial competitive edge by identifying material weaknesses and optimizing engine components for maximum efficiency and durability.

The Benefits of Thermal Testing Unlocking High-Temperature Performance

Enhanced Reliability With thermal testing, you can ensure that your materials will perform flawlessly in the most demanding conditions. By simulating real-world temperatures and stresses, we help identify potential failure points and prevent costly downtime.

Increased Efficiency Thermal testing enables optimization of engine components for maximum performance at high temperatures. This results in improved fuel efficiency, reduced emissions, and enhanced overall system reliability.

Compliance with Industry Standards Our thermal testing services are designed to meet or exceed industry standards, including those set by the Society of Automotive Engineers (SAE). By partnering with us, you can be confident that your materials will pass regulatory muster.

Improved Safety High-temperature performance is not just a matter of efficiency its also a critical safety consideration. Thermal testing helps identify potential hazards and ensures that your products meet or exceed safety standards.

Cost Savings By identifying material weaknesses early on, you can avoid costly re-designs, re-tooling, and production delays. Our thermal testing services help you pinpoint problem areas and make targeted improvements.

Competitive Advantage In todays fast-paced automotive industry, differentiation is key. By leveraging our thermal testing expertise, you can develop materials that outperform competitors and establish a market lead.

How Thermal Testing Works

Our comprehensive thermal testing program involves several key stages

Material Selection We work closely with clients to select the most suitable materials for their specific application.

Sample Preparation Samples are carefully prepared for testing, including any necessary surface treatments or coatings.

Thermal Cycling Materials are subjected to a controlled thermal cycle, simulating real-world temperature fluctuations and stresses.

Testing and Evaluation We monitor material performance during the test cycle, identifying areas of weakness and opportunities for improvement.

Reporting and Recommendations Our team provides detailed reports and actionable recommendations for optimizing material properties and improving high-temperature performance.

Frequently Asked Questions

Q What types of materials can be tested using thermal testing?

A We provide thermal testing services for a wide range of materials, including metals (alloys, steels), polymers, ceramics, and composites. Our expertise extends to various engine components, such as cylinder heads, pistons, valves, and exhaust systems.

Q What are the benefits of in-house versus outsourced thermal testing?

A While in-house testing can be convenient, it often lacks the specialized equipment, expertise, and resources needed for comprehensive thermal testing. Outsourcing to Eurolab ensures access to cutting-edge technology and experienced engineers who have worked with a broad range of materials.

Q How long does thermal testing typically take?

A The duration of our thermal testing services varies depending on the complexity of the project and the number of samples being tested. However, we work closely with clients to establish realistic timelines and ensure that results are delivered promptly.

Q Can I trust the accuracy of Eurolabs thermal testing results?

A Absolutely. Our team consists of experienced engineers who have developed a deep understanding of thermal testing principles and protocols. We adhere strictly to industry standards, ensuring that our results are reliable, reproducible, and actionable.

Conclusion

In todays high-performance automotive landscape, thermal testing is no longer a nicety its a necessity. By leveraging the expertise and capabilities offered by Eurolab, businesses can unlock unprecedented levels of efficiency, reliability, and safety in their engine components. Dont let material weaknesses hold you back trust us to help you conquer the challenges of high-temperature performance. Contact us today to explore how our thermal testing services can propel your business forward.