Testing for failure modes in defense materials under impact stress

Testing for Failure Modes in Defense Materials Under Impact Stress A Critical Laboratory Service Provided by Eurolab

In the defense industry, materials and equipment are subjected to extreme conditions that can cause catastrophic failures, compromising the safety of personnel and the effectiveness of missions. To mitigate these risks, companies must ensure their products and components can withstand various forms of stress, including impact. This is where testing for failure modes in defense materials under impact stress comes into play.

At Eurolab, our team of experts provides a comprehensive laboratory service designed to assess the vulnerability of defense materials to impact-related failures. By identifying potential weaknesses, manufacturers can optimize their products and minimize the risk of unexpected events.

The Importance of Impact Stress Testing

Impact stress is a critical factor in various military applications, including

Ballistic protection Materials used in body armor, helmets, and vehicle armor must be able to absorb and dissipate impact energy without failing.

Aircraft and helicopter components Turbine blades, engine parts, and other aircraft components are exposed to high-velocity impacts during takeoff and landing.

Naval vessels Hull materials must withstand the stresses of wave impact, propeller strikes, and other maritime-related incidents.

Failure modes under impact stress can be caused by various factors, including

Material weaknesses

Manufacturing defects

Design flaws

Environmental conditions

Advantages of Testing for Failure Modes in Defense Materials Under Impact Stress

Our laboratory service offers numerous benefits to defense manufacturers and organizations

Key Benefits of Our Laboratory Service

Improved material selection Identify the most suitable materials for your products, reducing the risk of premature failure.

Enhanced design optimization Refine product designs to minimize vulnerabilities and maximize performance under impact stress.

Reduced costs Avoid costly rework or replacement of failed components by identifying and addressing weaknesses early in the development process.

Increased safety Ensure personnel safety by verifying that materials can withstand expected impact stresses.

Compliance with industry standards Meet regulatory requirements for testing and evaluation, including those set by organizations such as NATO and ASTM.

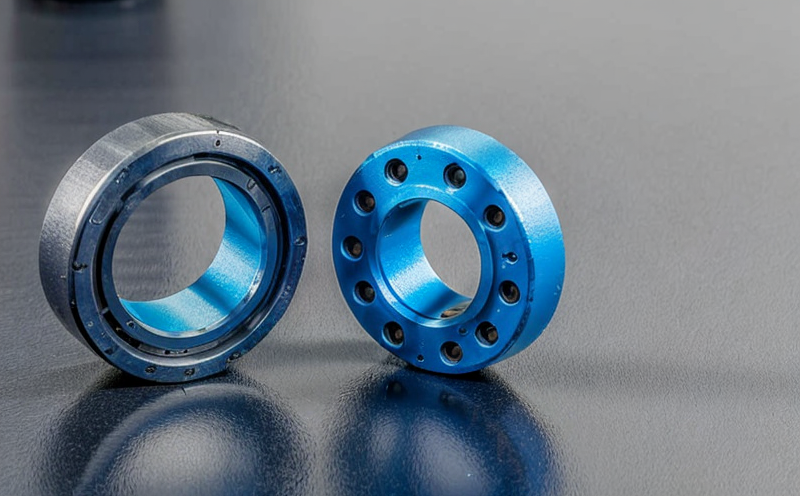

Comprehensive Testing Capabilities

Eurolab offers a range of testing services to evaluate the performance of defense materials under impact stress

Drop weight tower (DWT) testing Simulate high-velocity impacts using a controlled drop weight.

Projectile testing Evaluate material resistance to penetration by projectiles, including small arms and armor-piercing rounds.

Impact resonance testing Measure the dynamic response of materials to impact energy.

Case Studies

Our laboratory has assisted various defense companies in optimizing their products for improved performance under impact stress. For example

A leading manufacturer of ballistic protection systems used our services to evaluate the vulnerability of their armor panels to high-velocity impacts.

An aerospace company engaged us to test the durability of turbine blade materials under simulated engine conditions.

QA Section

Frequently Asked Questions

What types of materials can be tested for failure modes under impact stress?

Our laboratory services are applicable to a wide range of defense materials, including metals, polymers, ceramics, and composites.

How do you determine the appropriate testing protocol for each material or product?

We work closely with clients to develop customized test plans that address specific requirements and industry standards.

Can your laboratory services help improve the design of our products?

Yes, our expertise in materials science and engineering can inform product development decisions, ensuring optimal performance under impact stress.

Conclusion

In the defense industry, where reliability is paramount, testing for failure modes in defense materials under impact stress is a critical aspect of product development. By partnering with Eurolab, manufacturers can ensure their products meet or exceed performance expectations while minimizing the risk of unexpected failures.

Stay ahead of the competition and safeguard your personnel with confidence by leveraging our comprehensive laboratory services. Contact us to learn more about how we can assist you in optimizing your defense materials for impact stress resistance.