Tensile testing for adhesion failure in coatings

The Importance of Tensile Testing for Adhesion Failure in Coatings Ensuring Durability and Quality

In todays fast-paced manufacturing landscape, coatings play a vital role in protecting and enhancing the performance of various materials and products. From automotive paint to aerospace finishes, coatings are applied to ensure durability, corrosion resistance, and aesthetic appeal. However, adhesion failure can occur when the coating fails to bond properly with its substrate, leading to premature degradation and compromised performance.

Tensile testing for adhesion failure in coatings is a laboratory service provided by Eurolab that helps businesses detect and prevent such failures. In this article, well delve into the world of tensile testing, exploring its significance, advantages, and benefits in ensuring the quality and durability of coated products.

What is Tensile Testing for Adhesion Failure in Coatings?

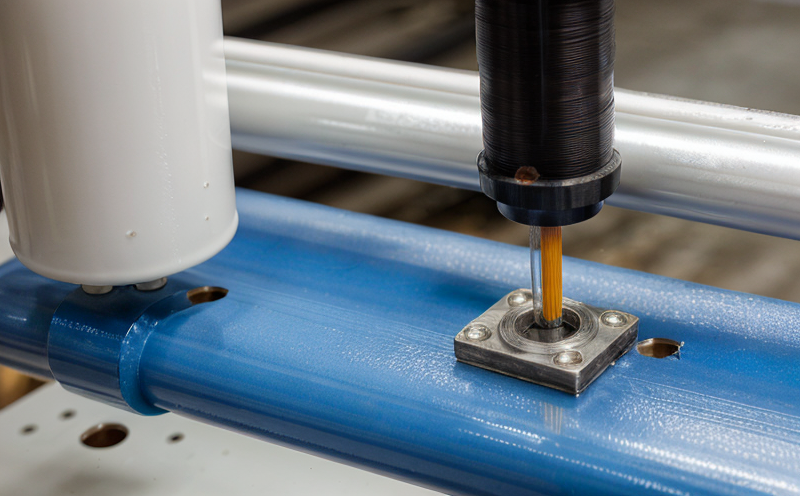

Tensile testing for adhesion failure in coatings is a non-destructive method used to evaluate the bond strength between a coating and its substrate. This laboratory service involves applying a controlled force to the sample until it fails, measuring the energy required to separate the coating from the substrate. The resulting data provides valuable insights into the adhesive properties of the coating, enabling manufacturers to assess its potential for adhesion failure.

Why is Tensile Testing for Adhesion Failure in Coatings Essential?

Adhesion failure can have significant consequences for businesses, including

Product Recalls Failure to detect adhesion issues can lead to product recalls, damaging a companys reputation and resulting in costly losses.

Material Waste Premature degradation of coatings due to adhesion failure can result in substantial material waste, affecting profitability and efficiency.

Safety Risks Adhesion failure can compromise the structural integrity of products, posing safety risks for users and operators.

Compliance Issues Failure to meet regulatory requirements related to coating performance can lead to fines and reputational damage.

Advantages of Tensile Testing for Adhesion Failure in Coatings

Eurolabs tensile testing service offers numerous benefits to businesses, including

Key Benefits

Early Detection Identify adhesion issues early on, preventing costly product recalls and material waste.

Improved Quality Control Enhance quality control measures by regularly testing coatings for adhesion failure.

Increased Efficiency Minimize production downtime and optimize resource allocation by detecting potential issues before they arise.

Compliance Assurance Demonstrate compliance with regulatory requirements related to coating performance.

Cost Savings Reduce waste, prevent recalls, and minimize losses associated with adhesion failure.

Tensile Testing for Adhesion Failure in Coatings How it Works

The process of tensile testing for adhesion failure involves the following steps

Sample Preparation Eurolabs experienced technicians prepare samples according to customer specifications.

Tensile Testing The sample is subjected to a controlled force until it fails, measuring the energy required to separate the coating from the substrate.

Data Analysis Results are analyzed and interpreted by Eurolabs team of experts.

QA Tensile Testing for Adhesion Failure in Coatings

Q What types of coatings can be tested using tensile testing?

A Eurolab provides tensile testing services for a wide range of coatings, including paint, varnish, and lacquer.

Q How do I know if my product requires tensile testing for adhesion failure?

A Contact Eurolab to discuss your specific needs and requirements. Our experts will assess whether tensile testing is necessary for your product.

Q Can tensile testing be performed on-site or must samples be sent to a laboratory?

A Samples can be sent to Eurolabs state-of-the-art laboratory, where our technicians will perform the testing.

Q How long does it take to receive results from tensile testing?

A Results are typically available within 24-48 hours of sample receipt.

Conclusion

Tensile testing for adhesion failure in coatings is a crucial service provided by Eurolab that helps businesses ensure the quality and durability of their products. By detecting potential issues early on, manufacturers can prevent costly losses associated with material waste and product recalls. With Eurolabs expertise and state-of-the-art laboratory facilities, you can rest assured that your coated products meet regulatory requirements and perform as intended.

Dont wait until its too late trust Eurolab to help you protect your business from the consequences of adhesion failure. Contact us today to learn more about our tensile testing services and take the first step towards ensuring the integrity of your coatings.