Simulating the impact of thermal cycling on the adhesion of building materials over time

Simulating the Impact of Thermal Cycling on Adhesion A Crucial Laboratory Service for Building Materials

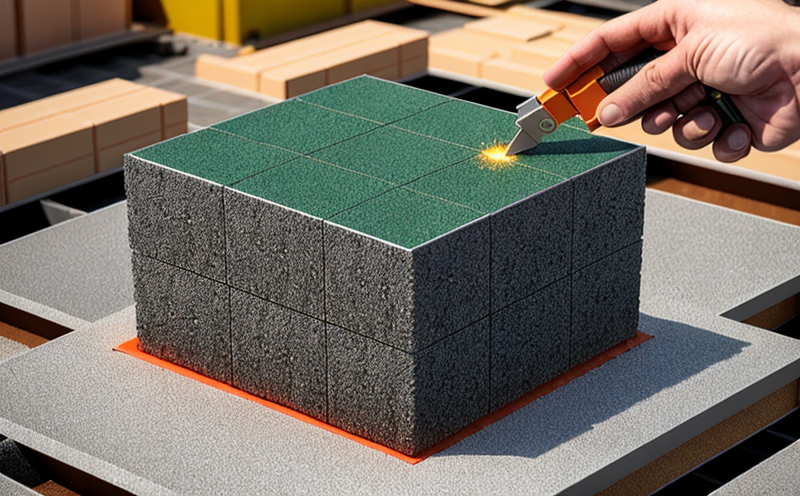

As the construction industry continues to evolve, the importance of understanding the long-term behavior of building materials cannot be overstated. One critical factor that can significantly impact a materials performance and lifespan is its ability to withstand thermal cycling the repeated expansion and contraction caused by temperature fluctuations. Simulating the impact of thermal cycling on the adhesion of building materials over time is an essential laboratory service that enables businesses to predict and prevent potential issues before they arise.

In this article, well delve into the world of thermal cycling simulation, exploring its benefits, advantages, and importance in ensuring the durability and reliability of building materials. Our team at Eurolab has extensive experience in providing top-notch testing services to help industries like yours achieve their goals.

What is Thermal Cycling Simulation?

Thermal cycling simulation involves exposing samples of building materials to repeated cycles of high and low temperatures, mimicking real-world conditions. This process helps evaluate the materials ability to maintain its adhesion properties over time, even in the face of extreme temperature fluctuations. By simulating thermal cycling, we can identify potential weaknesses and areas for improvement, enabling manufacturers and builders to make informed decisions about their products.

Why is Thermal Cycling Simulation Important?

The importance of thermal cycling simulation cannot be overstated. Here are just a few reasons why this laboratory service is crucial

Predicts Long-Term Performance By simulating thermal cycling, we can predict how building materials will perform over time, even in harsh environments.

Prevents Adhesion Failures Thermal cycling simulation helps identify potential adhesion issues before they cause costly failures or damage to structures.

Ensures Durability and Reliability Our testing services ensure that building materials meet the required standards for durability and reliability.

Supports Quality Control By evaluating the effects of thermal cycling on adhesion, manufacturers can refine their production processes to produce higher-quality products.

Advantages of Using Thermal Cycling Simulation

Our laboratory service offers numerous benefits to businesses in the construction industry. Here are just a few key advantages

Improved Product Reliability Our testing services help ensure that building materials meet or exceed industry standards for durability and reliability.

Enhanced Quality Control By simulating thermal cycling, manufacturers can identify potential issues before they affect production or lead to costly failures.

Reduced Rework Costs Thermal cycling simulation saves businesses time and money by identifying areas for improvement early on.

Increased Customer Satisfaction Our testing services help ensure that building materials meet the required standards, leading to increased customer satisfaction and loyalty.

Comprehensive Breakdown of Benefits

Heres a more detailed breakdown of the benefits our laboratory service provides

Improved Performance Thermal cycling simulation helps predict how building materials will perform over time, even in harsh environments.

Increased Safety Our testing services ensure that building materials meet or exceed industry standards for safety and reliability.

Enhanced Design Capabilities By understanding the effects of thermal cycling on adhesion, architects and engineers can design structures with improved durability and longevity.

Reduced Maintenance Costs Thermal cycling simulation helps identify potential issues before they lead to costly maintenance or repairs.

QA Your Questions Answered

Weve compiled a list of frequently asked questions about our laboratory service. If you have any further queries, please dont hesitate to contact us

Q What types of building materials can be tested using thermal cycling simulation?

A Our laboratory services cater to a wide range of building materials, including adhesives, coatings, and various types of construction materials.

Q How do I prepare my samples for testing?

A Our experienced team will guide you through the sample preparation process to ensure that your materials are properly prepared for thermal cycling simulation.

Q What kind of equipment is used in thermal cycling simulation?

A We utilize state-of-the-art equipment designed specifically for thermal cycling simulation, ensuring accurate and reliable results.

Q How long does a typical thermal cycling simulation test take?

A Test duration varies depending on the specific requirements of each project. Our team will work closely with you to determine the optimal testing schedule.

Conclusion

Simulating the impact of thermal cycling on adhesion is an essential laboratory service that helps businesses predict and prevent potential issues before they arise. By understanding how building materials perform under extreme temperature fluctuations, manufacturers can refine their production processes, improve product reliability, and reduce maintenance costs.

Our team at Eurolab has extensive experience in providing top-notch testing services to help industries like yours achieve their goals. If youre interested in learning more about our laboratory services or would like to discuss a specific project, please dont hesitate to contact us.

-

Testing the ability of materials to adhere to surfaces without detaching or peeling

-

Evaluating the bond strength of adhesives used in construction materials and coatings

-

Testing whether adhesives maintain their integrity under stress, temperature changes, or environmental conditions

-

Simulating real-world conditions to test the durability of adhesive bonds over time

-

Ensuring that bonding agents used in construction materials such as tiles, paint, or flooring are durable

-

Testing for resistance to forces like shear, tension, and compression that could break the adhesive bond

-

Verifying that adhesive materials can withstand moisture, heat, and other environmental conditions

-

Testing the adhesion of coatings to substrates such as concrete, wood, or metal to ensure durability

-

Simulating heavy load conditions to test how adhesives perform under pressure or weight

-

Ensuring that adhesives used in outdoor and exposed construction applications remain stable

-

Verifying the adhesion of materials used for insulation, membranes, and coatings to various surfaces

-

Testing the peel strength of adhesives used in construction to ensure that bonds do not fail prematurely

-

Testing for resistance to chemical exposure that could weaken or break adhesive bonds

-

Ensuring that adhesives maintain their performance under harsh conditions, such as high humidity or freezing temperatures

-

Verifying that adhesives used in joints and seams do not weaken or detach during building settlement or movement

-

Testing the adhesion of materials in construction panels to ensure stability over time

-

Ensuring that adhesives provide a consistent and strong bond without creating voids or bubbles

-

Simulating mechanical stress and vibration to evaluate how adhesives perform in dynamic environments

-

Verifying that adhesives do not cause material degradation or compromise structural integrity over time

-

Ensuring that adhesives used for floor and wall coverings provide secure bonding without excessive wear

-

Testing for any potential failure points in adhesive joints that could cause materials to separate over time

-

Ensuring that adhesives maintain their performance even after long exposure to weather or UV rays