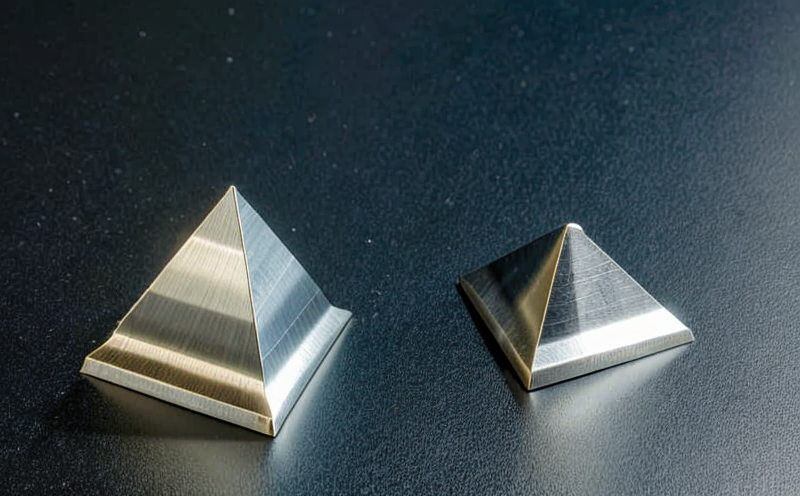

Simulating everyday use to assess whether sharp edges become exposed during product wear

The Ultimate Test for Product Safety Simulating Everyday Use to Assess Sharp Edges

In todays fast-paced world of manufacturing and product development, ensuring the safety and reliability of your products is paramount. With increasingly stringent regulations and consumer expectations, businesses are under pressure to guarantee that their products meet the highest standards of performance and safety.

One critical aspect of product safety is the assessment of sharp edges, which can pose a significant risk to users, particularly in high-traffic or high-risk environments. To mitigate this risk, Eurolab offers a specialized laboratory service Simulating Everyday Use to Assess Whether Sharp Edges Become Exposed During Product Wear. This innovative approach helps businesses like yours identify potential hazards and prevent costly recalls, injuries, or even fatalities.

Why Simulating Everyday Use Matters

Simulating everyday use is an essential tool for manufacturers seeking to ensure their products meet the demands of real-world usage. By replicating the stresses and strains that products will face in normal operation, businesses can identify potential weaknesses and take corrective action before its too late.

Sharp edges are a common concern across various industries, from consumer goods to industrial equipment. Even with rigorous testing and quality control measures in place, sharp edges can still become exposed during wear and tear. This is where Simulating Everyday Use comes into play to identify these potential hazards before they become major issues.

Advantages of Using Simulating Everyday Use

Our laboratory service offers a comprehensive suite of benefits that will revolutionize your product development process

Enhanced Product Safety By simulating everyday use, we can detect sharp edges and other hazards before they pose a risk to users.

Reduced Liability Minimize the likelihood of costly recalls, lawsuits, or reputational damage by identifying potential issues early on.

Increased Efficiency Our expertise will help you streamline your testing process, reducing time-to-market and saving resources.

Compliance with Regulations Stay ahead of industry standards and regulations by demonstrating a commitment to product safety.

Improved Customer Satisfaction Products that meet the highest safety standards build trust and loyalty among customers.

Key Benefits at a Glance

Here are the key advantages of using Simulating Everyday Use to assess whether sharp edges become exposed during product wear

Comprehensive testing Our team will subject your products to rigorous simulation, including environmental factors like temperature, humidity, and vibration.

Objective analysis We provide unbiased, scientifically-backed results that help you make informed decisions about product design and safety.

Cost savings By identifying potential issues early on, you can avoid costly re-designs or re-tooling processes.

Expert consultation Our experienced team will guide you through the testing process, offering valuable insights and recommendations for improvement.

QA Frequently Asked Questions About Simulating Everyday Use

Q What types of products benefit from Simulating Everyday Use?

A Any product with sharp edges or potential hazards can benefit from this service. This includes consumer goods, industrial equipment, medical devices, and more.

Q How do you simulate everyday use in the lab?

A We employ advanced testing methods to replicate real-world conditions, including mechanical stress, environmental factors, and user interaction.

Q What kind of data can I expect from the simulation process?

A Our expert analysts will provide detailed reports on product performance, identifying areas where sharp edges or other hazards may be present.

Q Can I use this service for regulatory compliance purposes?

A Yes! Our laboratory is equipped to support your regulatory obligations, providing evidence that your products meet industry standards and regulations.

Q How long does the simulation process typically take?

A The duration of the simulation depends on various factors, including product complexity and testing requirements. We will work closely with you to ensure timely completion.

Conclusion

In todays fast-paced business environment, prioritizing product safety is crucial for success. By utilizing Eurolabs Simulating Everyday Use service, manufacturers can identify potential hazards, reduce liability, and build trust among customers.

Dont risk the reputation or bottom line of your business choose a leading laboratory partner that shares your commitment to excellence. Contact us today to discuss how our expert team can help you simulate everyday use and ensure the highest standards of product safety for your products.

At Eurolab, were dedicated to helping businesses like yours achieve product excellence through innovative testing solutions. Lets work together to create safer, more reliable products that exceed consumer expectations and drive growth in your industry.

-

Testing consumer products to ensure they do not have sharp edges that could pose injury risks

-

Evaluating the safety of products by assessing potential hazards from sharp points or protrusions

-

Testing the edges of materials, such as metal, glass, and plastic, for smoothness and safety

-

Simulating real-world interactions with products to determine if sharp edges could cause cuts or punctures

-

Assessing the impact of sharp edges on children's toys, tools, or household items

-

Testing the effectiveness of protective covers or shields in preventing sharp edge injuries

-

Verifying the compliance of products with safety regulations related to sharp edge risks

-

Assessing the potential for scratches, punctures, or injury from edges in electronic devices or appliances

-

Testing for sharp edges on packaging materials and their potential impact during shipping or handling

-

Evaluating the design of consumer products to eliminate unnecessary sharp points in critical areas

-

Testing items like kitchenware, furniture, and automotive components for edge safety

-

Assessing the durability of edge protection features that prevent sharp edges from emerging over time

-

Evaluating materials used in product construction to ensure they can be safely handled without sharp edges

-

Testing for possible cuts or abrasions caused by sharp edges on clothing, textiles, or accessories

-

Verifying that products meet safety standards for edge smoothness and protection in consumer goods

-

Testing for sharp edges in products exposed to environmental wear, such as outdoor gear or tools

-

Ensuring that products with potential sharp edges have clear warnings or safety instructions

-

Assessing the impact of sharp edges in children's products or products intended for vulnerable populations

-

Testing for the formation of sharp edges during manufacturing or due to material degradation over time

-

Verifying the effectiveness of safety measures such as rounded corners or edge buffers