Simulating drops from different angles and heights to assess all-around durability

Assessing All-Around Durability Simulating Drops from Different Angles and Heights

In todays fast-paced business world, products are constantly being pushed to their limits. Whether its a new smartphone, a cutting-edge sports equipment, or a revolutionary medical device, manufacturers need to ensure that their products can withstand the rigors of everyday use. One crucial aspect of product development is testing its durability, particularly when it comes to falls and drops.

Thats where Eurolab comes in a leading laboratory service provider specializing in simulating drops from different angles and heights to assess all-around durability. In this article, well delve into the importance of this testing method, its numerous advantages, and what sets Eurolab apart as a premier laboratory services company.

What is Simulating Drops from Different Angles and Heights?

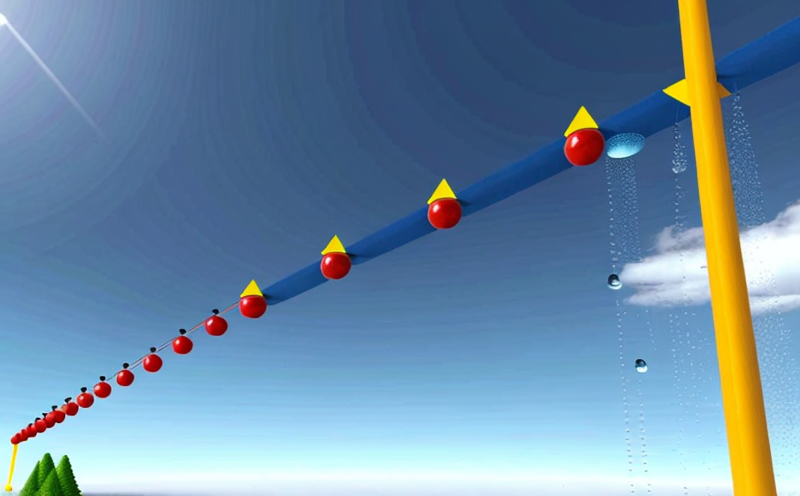

Simulating drops from different angles and heights involves subjecting products to controlled drop tests that mimic various real-world scenarios. This comprehensive approach helps manufacturers identify potential weaknesses in their designs, ensuring that their products can withstand the demands of daily use. By analyzing data from these simulations, businesses can make informed design decisions, optimize product performance, and ultimately reduce costs associated with product failures.

The Importance of Simulating Drops

In todays highly competitive market, businesses need to prioritize product reliability and safety. Consumers expect high-quality products that perform as expected, and manufacturers who fail to meet these expectations risk damage to their reputation and bottom line.

Simulating drops from different angles and heights is essential for several reasons

Compliance with regulations Many industries have specific standards governing product durability, such as ISO 10899 (Sports Equipment) or IEC 60068-2-30 (Environmental Testing). By conducting drop tests, manufacturers can ensure that their products meet these requirements.

Reducing product liability A durable product is less likely to cause injuries or damage. By simulating drops, manufacturers can identify potential hazards and mitigate risks associated with product liability.

Improving customer satisfaction Products that withstand everyday use are more likely to meet consumer expectations. This leads to increased customer satisfaction, loyalty, and ultimately, revenue growth.

Advantages of Using Simulating Drops

Eurolabs simulating drops from different angles and heights service offers numerous benefits for businesses

Key Benefits

Comprehensive understanding of product performance By analyzing data from drop tests, manufacturers gain a deeper understanding of their products strengths and weaknesses.

Reduced product development time Simulations enable designers to iterate quickly, making informed decisions that minimize the need for physical prototypes.

Increased customer trust When products demonstrate durability in simulated environments, consumers are more likely to trust them in real-world scenarios.

Competitive advantage Businesses that prioritize product reliability and safety stand out in their markets, attracting customers who value quality and performance.

Additional Benefits

Cost savings By identifying potential design flaws early on, manufacturers can avoid costly redesigns and retooling processes.

Improved supply chain efficiency When products are designed to withstand everyday use, suppliers and distributors can better manage inventory and shipping logistics.

Enhanced brand reputation Companies that prioritize product durability demonstrate a commitment to quality, which enhances their reputation and builds customer loyalty.

Technical Specifications

Eurolabs simulating drops from different angles and heights service is conducted using state-of-the-art equipment, including

Custom-built drop towers for precise control over height and angle

High-speed cameras for capturing detailed footage of product impact

Advanced data analysis software for extracting relevant insights from test data

Frequently Asked Questions

Q What types of products can be tested using simulating drops?

A Eurolabs service is suitable for a wide range of products, including but not limited to

Electronics (smartphones, tablets, laptops)

Sports equipment (helmets, bikes, golf clubs)

Medical devices (orthotics, prosthetics, medical implants)

Q How do I prepare my product for drop testing?

A Before conducting a drop test, manufacturers should ensure their products are properly packaged and prepared for impact. This may involve securing loose components or protecting sensitive areas.

Q What kind of data can I expect from a simulated drop test?

A Eurolabs analysis software provides detailed reports on product performance, including

Impact force and energy transfer

Deformation and damage analysis

Failure mode identification

By partnering with Eurolab for simulating drops from different angles and heights, businesses can confidently assess their products all-around durability. Our team of experts is dedicated to providing accurate data-driven insights that inform design decisions and drive innovation.

Join the ranks of industry leaders who trust Eurolabs laboratory services to ensure their products meet the highest standards of quality and performance. Contact us today to learn more about our comprehensive testing solutions and take your product development to the next level.