Seal integrity testing for aerospace applications

Ensuring Flight Worthiness Seal Integrity Testing for Aerospace Applications with Eurolab

In the aerospace industry, even the smallest margin of error can have catastrophic consequences. With billions of dollars invested in each project and thousands of lives at stake, its essential to guarantee the safety and reliability of every component, system, and subsystem. One critical aspect that often receives less attention is seal integrity testing for aerospace applications. This specialized laboratory service is a crucial step in ensuring the airtight seals within aircraft and spacecraft are functioning as intended.

What is Seal Integrity Testing?

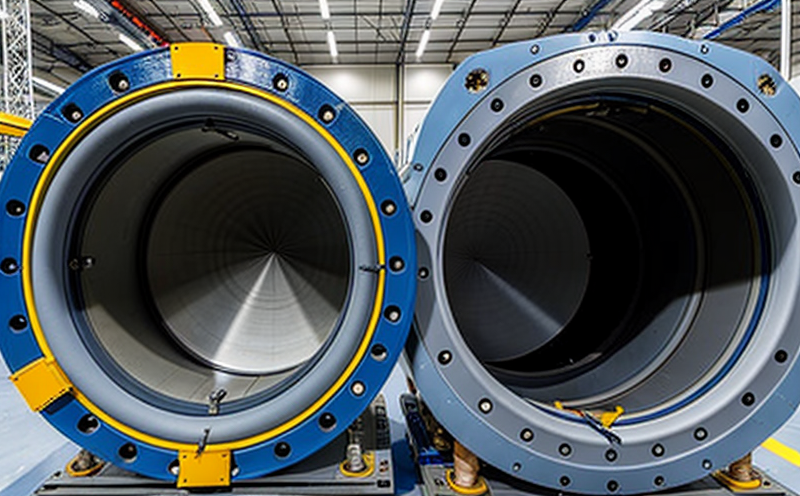

Seal integrity testing involves evaluating the performance of mechanical seals used to maintain air or fluid tightness within an aircrafts systems, such as fuel tanks, hydraulic lines, and pressurized compartments. These seals must withstand extreme temperatures, pressures, and environmental conditions, which can cause them to degrade over time.

Why is Seal Integrity Testing Essential for Aerospace Applications?

In the aerospace industry, failure of a single seal can have devastating consequences, including

Loss of aircraft or spacecraft A compromised seal can lead to catastrophic system failures, putting lives at risk and causing billions of dollars in damage.

Increased maintenance costs Regularly inspecting and replacing seals can be costly, but neglecting them can result in even higher expenses due to system failures.

Extended downtime Seal failure can force an aircraft or spacecraft out of service for extended periods, impacting mission schedules and overall program efficiency.

Benefits of Using Eurolabs Seal Integrity Testing Services

Our team at Eurolab understands the importance of thorough seal integrity testing. Here are just a few key benefits of using our services

Improved safety By identifying potential seal issues early on, we help ensure that your aircraft or spacecraft meets strict safety standards.

Reduced maintenance costs Regular seal inspections can help prevent costly repairs and replacements down the line.

Increased efficiency With our testing services, you can avoid unexpected system failures and maintain a smooth flight schedule.

Key Benefits of Seal Integrity Testing

Compliance with regulations Our testing meets or exceeds industry standards for aerospace seal integrity.

Accurate results We utilize state-of-the-art equipment and techniques to provide precise seal performance evaluations.

Rapid turnaround times Our experienced team works efficiently to ensure quick test completion, minimizing downtime.

QA Seal Integrity Testing with Eurolab

Here are some frequently asked questions about our seal integrity testing services

Q What types of seals can you test?

A We can evaluate a wide range of mechanical seals used in various aerospace applications.

Q How do I prepare my samples for testing?

A Our team will provide detailed instructions on how to properly package and ship your samples.

Q Can you provide certification or documentation for our seal integrity test results?

A Yes, we can supply comprehensive reports that meet industry standards.

Trust Eurolab with Your Seal Integrity Testing Needs

In the high-stakes world of aerospace, trust is paramount. Our team at Eurolab has extensive experience providing precise and reliable laboratory services to ensure your seals are functioning as intended. Dont let a single component compromise the safety and reliability of your aircraft or spacecraft. Choose us for your seal integrity testing needs and rest assured that well work diligently to help you meet industry standards.

Contact us today to learn more about our laboratory services and how we can support your aerospace projects success.