Methods for mechanical integrity evaluation

Ensuring Mechanical Integrity The Crucial Role of Eurolabs Methods for Mechanical Integrity Evaluation

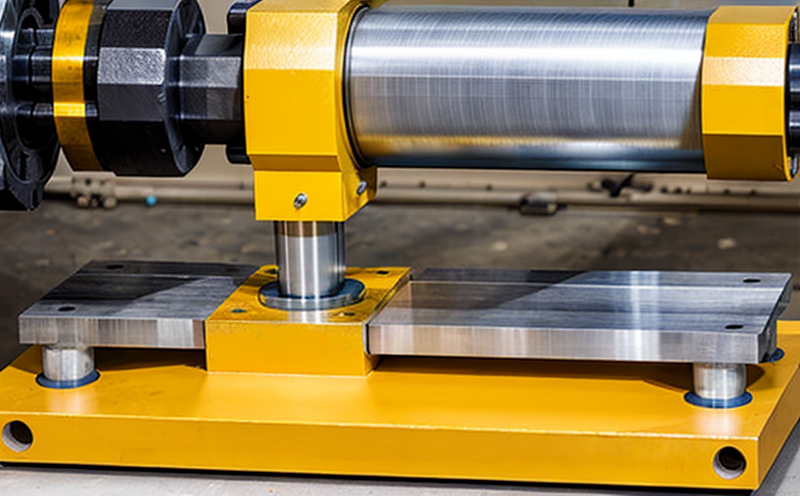

In the world of industry and manufacturing, maintaining mechanical integrity is a top priority. Its a vital aspect that ensures equipment operates safely, efficiently, and effectively throughout its lifespan. Without it, businesses risk downtime, costly repairs, and even more serious consequences like injuries or fatalities. This is where Eurolabs Methods for Mechanical Integrity Evaluation come in a sophisticated laboratory service designed to help companies like yours assess and maintain the mechanical integrity of their equipment.

What is Methods for Mechanical Integrity Evaluation?

In simple terms, Methods for Mechanical Integrity Evaluation refers to a set of procedures used to evaluate the condition of mechanical systems and equipment. These evaluations are performed by expert technicians who use state-of-the-art tools and techniques to identify potential issues before they become major problems. By doing so, companies can prevent costly repairs, reduce downtime, and ensure compliance with regulatory standards.

Why is Methods for Mechanical Integrity Evaluation Essential?

In todays fast-paced business environment, companies face numerous challenges that can compromise mechanical integrity. Some of these include

Aging equipment

Increased operational pressures

Inadequate maintenance

Insufficient training

These factors can lead to a range of issues, including reduced performance, premature failure, and safety hazards. Thats where Eurolabs Methods for Mechanical Integrity Evaluation come in providing businesses with the tools they need to maintain mechanical integrity and ensure a safe working environment.

Advantages of Using Methods for Mechanical Integrity Evaluation

The benefits of using Eurolabs Methods for Mechanical Integrity Evaluation are numerous

Identify Potential Issues Before They Become Major Problems Regular evaluations help companies detect potential issues before they escalate into major problems, reducing the risk of costly repairs and downtime.

Improve Safety By identifying hazards and taking corrective action, businesses can ensure a safer working environment for employees and reduce the risk of accidents.

Enhance Equipment Performance Methods for Mechanical Integrity Evaluation helps optimize equipment performance by identifying areas for improvement and providing recommendations for maintenance and repair.

Reduce Energy Consumption Regular evaluations enable companies to identify opportunities to improve energy efficiency, reducing costs and environmental impact.

Comply with Regulatory Standards Eurolabs Methods for Mechanical Integrity Evaluation ensures compliance with regulatory standards, protecting businesses from fines and reputational damage.

Some of the key benefits of using Eurolabs laboratory service include

Increased Efficiency By identifying potential issues early on, companies can reduce downtime and improve overall efficiency.

Cost Savings Regular evaluations help prevent costly repairs and maintenance, saving businesses money in the long run.

Improved Safety Record Methods for Mechanical Integrity Evaluation ensures a safer working environment, reducing the risk of accidents and improving employee morale.

Enhanced Productivity Optimized equipment performance leads to increased productivity, enabling companies to meet growing demands and stay competitive.

Reduced Environmental Impact Regular evaluations help businesses identify opportunities to improve energy efficiency, reducing their environmental footprint.

QA Section Your Questions Answered

We understand that you may have questions about Eurolabs Methods for Mechanical Integrity Evaluation. Here are some frequently asked questions (FAQs) and answers

Q What types of equipment can be evaluated?

A Our laboratory service covers a wide range of equipment, including pressure vessels, storage tanks, piping systems, pumps, and more.

Q How often should I have my equipment evaluated?

A Regular evaluations are recommended every 5-10 years, depending on factors like usage, industry standards, and regulatory requirements.

Q What happens during a Methods for Mechanical Integrity Evaluation?

A Our expert technicians will conduct a thorough examination of your equipment, using state-of-the-art tools and techniques to identify potential issues.

Q Will the evaluation process disrupt my operations?

A We strive to minimize downtime and ensure that our evaluations are conducted with minimal disruption to your business operations.

Q What kind of report can I expect after the evaluation?

A Our comprehensive report will outline any findings, recommendations for maintenance or repair, and suggestions for improving equipment performance.

Conclusion

Maintaining mechanical integrity is a critical aspect of industry and manufacturing. Eurolabs Methods for Mechanical Integrity Evaluation provides businesses with the tools they need to ensure their equipment operates safely, efficiently, and effectively throughout its lifespan. By using our laboratory service, companies can identify potential issues before they become major problems, reduce downtime and costs, and enhance overall performance.

Dont wait until its too late contact Eurolab today to schedule a Methods for Mechanical Integrity Evaluation. Our expert technicians will work with you to ensure your equipment operates at its best, protecting your business from costly repairs, safety hazards, and reputational damage.

About Eurolab

Eurolab is a leading provider of laboratory services, specializing in Methods for Mechanical Integrity Evaluation. Our team of expert technicians has years of experience in evaluating mechanical systems and equipment, providing businesses with the tools they need to maintain mechanical integrity and ensure a safe working environment.

By choosing Eurolab, you can trust that your equipment will be evaluated by professionals who understand the importance of mechanical integrity in industry and manufacturing. Contact us today to learn more about our Methods for Mechanical Integrity Evaluation laboratory service and schedule an evaluation for your business.