Fracture toughness evaluation for composites

The Crucial Role of Fracture Toughness Evaluation for Composites Why Your Business Needs It

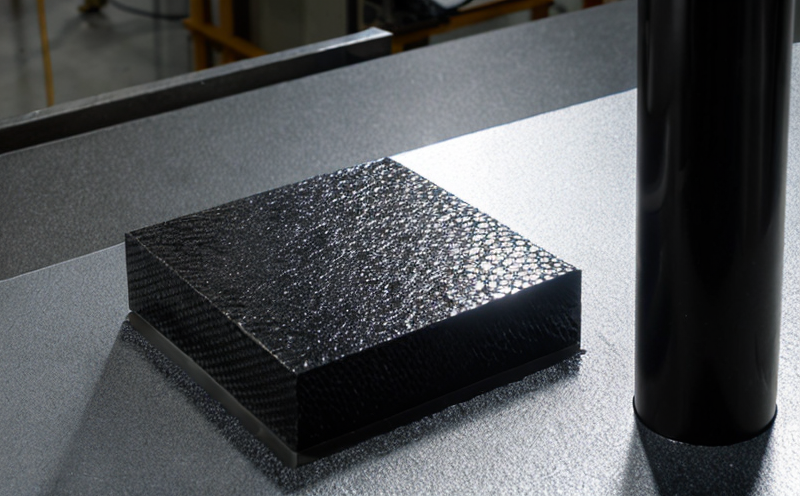

In the world of materials science and engineering, composites have revolutionized the way we design and manufacture products. From aircraft components to medical devices, composites are used extensively due to their exceptional strength-to-weight ratio, corrosion resistance, and ability to be tailored to specific properties. However, with great performance comes great responsibility ensuring that these composite materials can withstand the stresses and strains of real-world applications is paramount.

Fracture toughness evaluation for composites is a critical laboratory service provided by Eurolab that helps businesses like yours guarantee the reliability and durability of their products. In this article, well delve into the importance of fracture toughness evaluation, its benefits, and why its essential for companies operating in various industries.

What is Fracture Toughness Evaluation for Composites?

Fracture toughness evaluation involves determining a materials ability to resist crack propagation and subsequent failure under stress. This critical property is essential for composite materials, which can be prone to catastrophic failure due to their complex microstructure and anisotropic behavior.

Eurolabs fracture toughness evaluation service uses standardized test methods to assess the resistance of composites to sudden failures, providing valuable insights into their performance in various environments. By understanding a materials fracture toughness, manufacturers can optimize design parameters, select suitable materials for specific applications, and ensure compliance with industry standards and regulations.

Advantages of Using Fracture Toughness Evaluation for Composites

The benefits of incorporating fracture toughness evaluation into your quality control process are numerous

Reduced Risk of Catastrophic Failure By identifying potential weaknesses in composite materials, manufacturers can minimize the risk of catastrophic failures, which can have severe consequences on product performance, safety, and reputation.

Improved Product Reliability Fracture toughness evaluation enables companies to design products with optimized material properties, resulting in enhanced reliability and reduced warranty claims.

Enhanced Material Selection By understanding a composites fracture toughness, manufacturers can select materials tailored to specific applications, leading to improved product performance, weight reduction, and cost savings.

Compliance with Industry Standards Fracture toughness evaluation ensures that products meet or exceed industry standards and regulations, such as those set by ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization).

Cost Savings through Reduced Testing Time Eurolabs expertise in fracture toughness evaluation enables companies to minimize testing time, reducing the need for extensive trial-and-error experiments.

Competitive Advantage By prioritizing fracture toughness evaluation, businesses can differentiate themselves from competitors by demonstrating a commitment to quality and safety.

Comprehensive QA Section

Weve compiled a list of frequently asked questions to address common queries about fracture toughness evaluation

Q What types of composite materials can be evaluated?

A Eurolabs fracture toughness evaluation service is applicable to various composite materials, including carbon fiber reinforced polymers (CFRP), glass fiber reinforced polymers (GFRP), and hybrid composites.

Q How do you conduct the fracture toughness evaluation?

A Our expert technicians use standardized test methods, such as the single-edge notched bending (SENB) or compact tension (CT) tests, to assess the materials resistance to crack propagation.

Q What are the benefits of using a laboratory like Eurolab for fracture toughness evaluation?

A By outsourcing this critical service to a specialized laboratory like Eurolab, companies can ensure accurate and reliable results, saving time and resources that would be required to establish in-house testing capabilities.

Q Can I perform fracture toughness evaluation in-house?

A While its technically possible to conduct fracture toughness evaluation in-house, the expertise and equipment required make it challenging. Outsourcing this service to a specialized laboratory like Eurolab ensures accuracy, reliability, and compliance with industry standards.

Q What are the typical turnaround times for fracture toughness evaluation results?

A Eurolabs experienced team works efficiently to provide timely results, usually within 2-4 weeks, depending on the complexity of the test.

Conclusion

Fracture toughness evaluation is an essential laboratory service that helps businesses like yours guarantee the reliability and durability of composite products. By understanding a materials fracture toughness, manufacturers can optimize design parameters, select suitable materials for specific applications, and ensure compliance with industry standards and regulations.

At Eurolab, our experts in fracture toughness evaluation are dedicated to providing accurate and reliable results, ensuring that your business stays ahead of the competition. Dont compromise on product quality choose Eurolabs comprehensive laboratory services to guarantee the success of your composite products.

Additional Information

For more information about Eurolabs fracture toughness evaluation service or to learn how our laboratory can support your business, please visit our website and explore our range of materials testing services.