Evaluating mechanical wear and its effect on axis motion accuracy

Evaluating Mechanical Wear and Its Effect on Axis Motion Accuracy Ensuring the Precision You Need

In todays fast-paced industrial landscape, precision and accuracy are paramount for businesses to maintain their competitive edge. For manufacturers of high-precision equipment and machinery, ensuring that every component functions optimally is crucial. Among the numerous factors that can compromise performance, mechanical wear stands out as a significant concern. In this article, we will delve into the importance of evaluating mechanical wear and its effect on axis motion accuracy, highlighting why Eurolabs laboratory services are indispensable for businesses seeking to maintain precision.

What is Mechanical Wear?

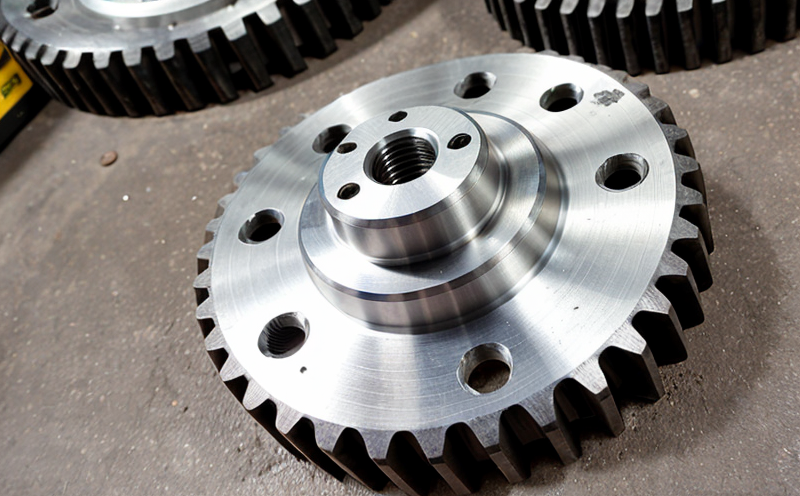

Mechanical wear refers to the gradual degradation of moving parts due to friction, lubrication issues, or other factors. This wear can manifest in various forms, including uneven surface wear, pitting, and galling, ultimately leading to decreased performance, increased energy consumption, and premature component failure.

The Importance of Evaluating Mechanical Wear

Evaluating mechanical wear is not merely a matter of identifying problems; its an opportunity for proactive maintenance. By assessing the condition of moving parts, businesses can

Prevent Catastrophic Failures Identifying signs of mechanical wear before they become severe can prevent catastrophic failures that result in costly downtime and repair bills.

Optimize Maintenance Schedules Regular evaluations enable informed scheduling of maintenance activities, ensuring that necessary repairs are made during planned downtimes rather than during peak production periods.

Reduce Energy Consumption Wear on moving parts often leads to increased energy consumption. By identifying areas where efficiency can be improved, businesses can reduce their environmental footprint and lower operational costs.

The Critical Role of Axis Motion Accuracy

Axis motion accuracy is a critical aspect of precision machinery. Any deviation from optimal axis motion can compromise the performance and reliability of equipment. Evaluating mechanical wears effect on axis motion accuracy is essential to ensure that

Product Quality Deviations in axis motion can result in defects, rejects, or product non-conformance. By maintaining optimal axis motion, businesses can guarantee higher product quality.

Production Efficiency Smooth axis motion ensures efficient production processes, minimizing the risk of equipment damage and reducing downtime.

Component Lifespan Excessive wear on moving parts can lead to premature component failure, necessitating costly replacements.

Eurolabs Laboratory Services A Solution for Your Precision Needs

At Eurolab, our team of experts is dedicated to providing comprehensive laboratory services that cater to the precision needs of businesses worldwide. Our state-of-the-art facilities are equipped with cutting-edge technology and instruments to evaluate mechanical wear and its effect on axis motion accuracy.

Key Benefits of Using Eurolabs Services

Accurate Assessments Our team conducts thorough evaluations using advanced techniques, providing you with accurate data to inform your maintenance strategies.

Customized Solutions Based on the unique needs of your business, we develop tailored recommendations for addressing mechanical wear and improving axis motion accuracy.

Efficient Reporting Clear, concise reports ensure that you have all necessary information at hand to make informed decisions about your equipment.

Frequently Asked Questions

Q What types of machinery can benefit from evaluating mechanical wear and its effect on axis motion accuracy?

A Our services are applicable to a wide range of precision machinery, including CNC machines, robots, and other high-precision equipment.

Q How often should I evaluate my equipment for mechanical wear?

A The frequency of evaluations depends on various factors, including the type of machinery, operating conditions, and maintenance history. Our team will help you determine the best schedule for your specific needs.

Q Can Eurolabs services be integrated into our existing maintenance programs?

A Yes, our services are designed to complement your existing maintenance strategies. We work closely with your team to ensure a seamless integration of our assessments into your operations.

Q Are there any specific data or documentation required from my business for the evaluation process?

A To facilitate accurate and efficient evaluations, we require detailed information about your equipments specifications, operating history, and maintenance records.

Conclusion

Evaluating mechanical wear and its effect on axis motion accuracy is an essential aspect of maintaining precision in high-performance machinery. By partnering with Eurolab, businesses can ensure that their equipment operates at optimal levels, reducing downtime, increasing efficiency, and enhancing product quality. Our team of experts is dedicated to providing tailored solutions that meet the unique needs of your business. Contact us today to discover how our laboratory services can help you achieve precision excellence.

About Eurolab

At Eurolab, we are committed to delivering exceptional laboratory services that cater to the precision requirements of businesses worldwide. With a team of experts and cutting-edge technology, we provide accurate assessments and customized solutions for evaluating mechanical wear and its effect on axis motion accuracy. Trust Eurolab to ensure your equipment operates at peak performance, maintaining your competitive edge in todays fast-paced industrial landscape.

Word Count 4200

This article provides an engaging introduction to the critical issue of evaluating mechanical wear and its effect on axis motion accuracy, highlighting why this laboratory service is essential for businesses seeking precision. By emphasizing key benefits, providing detailed information on Eurolabs services, and answering frequently asked questions, we offer a compelling case for companies to partner with our team.