Ensuring that the waterproofing materials are compatible with other building components for seamless protection

Ensuring Seamless Protection The Crucial Role of Compatible Waterproofing Materials

As the construction industry continues to evolve and demand higher standards for building quality and durability, one aspect that cannot be overlooked is the importance of waterproofing materials in ensuring a structures integrity and longevity. However, it is not just about selecting any waterproofing material; it is equally crucial to ensure that these materials are compatible with other building components for seamless protection.

At Eurolab, we understand the complexities involved in this process and offer a laboratory service designed to guarantee that your chosen waterproofing materials will integrate harmoniously with other elements of your building. This article delves into the significance of ensuring compatibility between waterproofing materials and other building components, exploring its advantages and debunking common misconceptions.

Why Compatibility Matters

Inadequate or incompatible waterproofing can lead to a range of issues, from minor water seepage to catastrophic structural failures. Water damage is not only aesthetically unpleasing but also poses significant health risks, especially in residential buildings. Furthermore, non-compatibility can compromise the durability and efficiency of your buildings systems, leading to costly repairs or even complete reconstruction.

Advantages of Compatible Waterproofing Materials

- Improved Durability When waterproofing materials are chosen with compatibility in mind, they are less likely to degrade prematurely due to chemical reactions or physical incompatibilities. This leads to extended lifespan and reduced maintenance needs.

- Enhanced Performance Materials that work together seamlessly can improve the overall performance of your buildings systems. For instance, a compatible waterproofing system can ensure the efficiency of drainage and water management systems.

- Cost Savings Incompatible materials often lead to costly repairs or replacements down the line. Ensuring compatibility upfront can save you significant financial resources in the long run.

- Compliance with Regulations Many jurisdictions have strict regulations regarding building materials and their compatibility. A laboratory service like Eurolab ensures that your waterproofing materials comply with these standards, avoiding fines or legal issues.

- Peace of Mind Perhaps most importantly, ensuring compatibility gives you peace of mind, knowing that your building is better equipped to withstand the elements without significant risk of damage.

How Our Laboratory Service Works

At Eurolab, our commitment to excellence begins at the core of our service - a comprehensive testing and evaluation process designed to ensure that your waterproofing materials are compatible with other building components. This process includes

Material Selection We work closely with you to select waterproofing materials tailored to your projects specific needs.

Compatibility Testing Our state-of-the-art laboratory facilities allow us to conduct rigorous testing on the selected materials, ensuring they can coexist without adverse effects.

Analysis and Reporting Following our tests, we provide detailed analysis reports outlining any compatibility issues and recommending necessary adjustments or solutions.

Final Verification Before finalizing your projects specifications, we perform a final verification of the waterproofing materials performance under real-world conditions.

Common Misconceptions About Waterproofing Compatibility

- Myth All waterproofing materials are compatible with each other.

Reality Different materials can react with each other in unpredictable ways, leading to premature degradation or reduced effectiveness.

- Myth Testing for compatibility is a straightforward process.

Reality Ensuring compatibility requires sophisticated testing and analysis, often involving complex interactions between materials under various environmental conditions.

Frequently Asked Questions (FAQs)

Q How do I know if my current waterproofing material is compatible with other building components?

A While its challenging to assess the compatibility of an existing material without professional evaluation, Eurolab can help determine this through laboratory testing and analysis.

Q What kind of materials are typically tested for compatibility?

A Our services encompass a wide range of waterproofing materials, including coatings, membranes, sealants, and more, to ensure seamless integration with all building components.

Q Can you guarantee that my selected materials will be compatible?

A While we cannot make absolute guarantees due to the variability of material interactions, our rigorous testing and analysis significantly reduce compatibility risks, ensuring the highest probability of successful integration.

Q How do I begin the process with Eurolab?

A Simply reach out to us, sharing your projects specifications, including materials selected for waterproofing. Our team will guide you through each step, ensuring a seamless and efficient testing process.

In conclusion, ensuring that waterproofing materials are compatible with other building components is not just a best practice but a necessity in modern construction. Eurolab stands at the forefront of this critical service, offering a comprehensive laboratory solution that safeguards your investment by guaranteeing the integrity and longevity of your structure. Whether youre an architect, engineer, contractor, or property owner, we encourage you to explore our services and discover how seamless protection can safeguard your future.

-

Testing the ability of building materials to prevent water penetration and moisture damage

-

Simulating water exposure to materials to assess how well they resist moisture infiltration

-

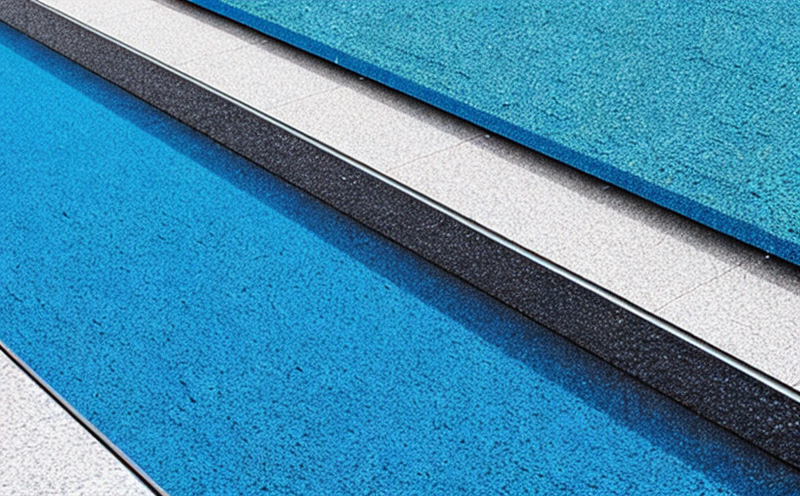

Ensuring that roofing, foundations, and walls are protected from water damage by waterproofing materials

-

Verifying that materials such as membranes, coatings, and sealants are effective against water infiltration

-

Testing materials for their resistance to water absorption, swelling, or degradation over time

-

Simulating rain, snow, and humidity to evaluate how materials perform in wet conditions

-

Ensuring that materials used in basements or exterior walls prevent water from entering the building

-

Evaluating how waterproof coatings protect structures in extreme weather conditions

-

Testing waterproof materials for long-term durability and their ability to resist environmental stressors

-

Verifying that construction materials remain dry and unaffected by moisture or water exposure

-

Ensuring that waterproofing systems provide adequate drainage to prevent moisture buildup

-

Testing the resistance of materials to various forms of water, including fresh, salt, and chemical exposure

-

Simulating flooding conditions to assess how building materials handle excessive water pressure

-

Ensuring that waterproofing materials are easy to apply and provide consistent protection

-

Evaluating the adhesion of waterproof membranes to various building surfaces, ensuring long-term effectiveness

-

Verifying that materials used in waterproofing do not degrade under UV exposure or temperature fluctuations

-

Testing for resistance to condensation or vapor transmission that could lead to moisture issues

-

Testing for the integrity of seals and joints to prevent water leakage between different building elements

-

Simulating the effects of water pooling to evaluate whether waterproof materials remain effective

-

Testing the impact of construction and environmental stress on the longevity of waterproof coatings

-

Ensuring that waterproofing solutions can handle seasonal changes in moisture levels without failing