Dielectric Strength Testing in Aerospace Electronics

The Crucial Role of Dielectric Strength Testing in Aerospace Electronics Ensuring Reliability and Safety

In the highly competitive world of aerospace electronics, reliability and safety are paramount. The slightest compromise in either can have devastating consequences, ranging from costly delays to catastrophic failures that put lives at risk. One critical laboratory service that plays a pivotal role in ensuring the integrity of these complex electronic systems is Dielectric Strength Testing (DST). At Eurolab, we specialize in providing this essential testing service to businesses operating within the aerospace sector.

What is Dielectric Strength Testing in Aerospace Electronics?

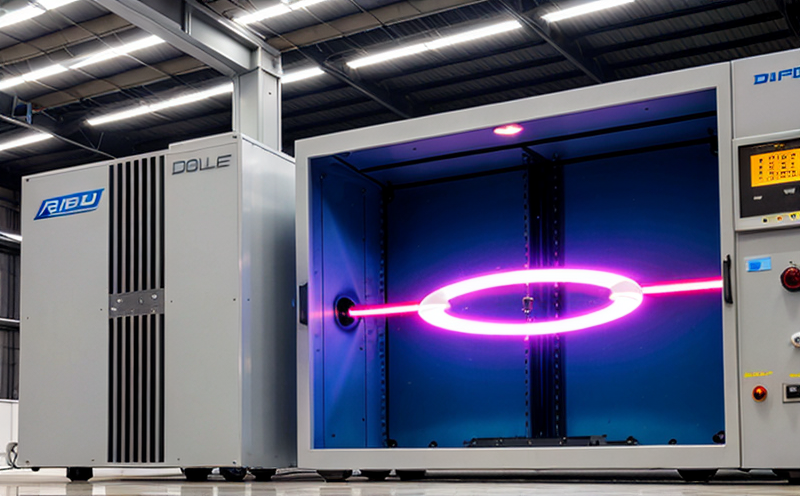

Dielectric Strength Testing is a non-destructive evaluation method used to assess the dielectric strength of materials and components in aerospace electronics. This critical parameter determines the ability of an insulating material to withstand electrical stresses without failing or breaking down. In simple terms, DST measures the maximum voltage that can be applied across a material before it breaks down, providing valuable insights into its reliability under operational conditions.

Why is Dielectric Strength Testing Essential for Aerospace Electronics?

The use of Dielectric Strength Testing in aerospace electronics offers numerous advantages, including

Enhanced Reliability By identifying potential weaknesses and vulnerabilities, DST helps manufacturers ensure the reliability of their electronic systems, reducing the likelihood of failures and downtime.

Improved Safety Accurate dielectric strength testing prevents catastrophic failures, which can have far-reaching consequences for human life and safety.

Reduced Costs Early detection of material or component issues through DST can help avoid costly redesigns, rework, or even system replacement.

Compliance with Regulations By demonstrating compliance with rigorous standards, manufacturers can meet industry regulations and certification requirements, maintaining a strong reputation in the market.

Key Benefits of Dielectric Strength Testing

Preventative Maintenance DST allows for proactive identification of potential issues before they become major problems, ensuring that maintenance activities are focused on critical areas.

Reduced Testing Time With our advanced testing equipment and experienced technicians, we can quickly and accurately determine the dielectric strength of materials, saving valuable time in product development cycles.

Multi-Parameter Analysis DST provides a comprehensive understanding of material behavior under various environmental conditions, including temperature, humidity, and voltage stress.

Customized Testing Solutions Eurolab offers tailored testing services to meet specific client requirements, ensuring that our tests are aligned with their unique product specifications.

Frequently Asked Questions

Q What types of materials can be tested using Dielectric Strength Testing?

A DST is applicable to a wide range of materials commonly used in aerospace electronics, including ceramics, polymers, glass, and composites.

Q How does Eurolab ensure accurate results from Dielectric Strength Testing?

A Our experienced technicians undergo rigorous training and adhere to strict quality control procedures, utilizing state-of-the-art equipment to deliver precise and reliable test results.

Q What are the standard testing conditions for Dielectric Strength Testing in aerospace electronics?

A DST is typically performed under standard atmospheric conditions (22C 2C and 50 10 relative humidity) with voltage applied across the material until breakdown occurs.

Q Can Dielectric Strength Testing be used to evaluate the reliability of existing products or systems?

A Yes, our DST services are also suitable for assessing the dielectric strength of legacy components or entire electronic systems, helping manufacturers identify potential weaknesses and optimize maintenance schedules.

Conclusion

Dielectric Strength Testing is a crucial laboratory service that plays a vital role in ensuring the reliability and safety of aerospace electronics. By identifying material vulnerabilities and optimizing system design, DST helps manufacturers reduce costs, meet regulatory requirements, and maintain a strong reputation in the market. At Eurolab, our team of experienced technicians and state-of-the-art equipment ensure accurate and reliable results from this essential testing service.

Choose Eurolab for Your Dielectric Strength Testing Needs

Dont compromise on the reliability and safety of your aerospace electronics products or systems. Trust Eurolabs expertise in Dielectric Strength Testing to help you achieve success in the competitive world of space exploration and satellite technology.

By selecting our laboratory services, youll gain access to

Industry-recognized testing standards We adhere to strict quality control procedures and utilize internationally recognized testing standards.

Expert technicians Our experienced team is dedicated to delivering precise and reliable results from Dielectric Strength Testing.

State-of-the-art equipment Our advanced testing equipment ensures accurate and repeatable measurements, providing confidence in our test results.

Partner with Eurolab for peace of mind when it comes to the reliability and safety of your aerospace electronics products or systems. Contact us today to learn more about how we can help you achieve success in the industry.