Unlock the Secrets of Your Materials with Coma Distortion Testing from Eurolab

In todays fast-paced business world, materials play a crucial role in the production and manufacturing processes of various industries. From automotive to aerospace, and from consumer goods to industrial equipment, the performance and quality of materials can make all the difference between success and failure. One critical aspect that often gets overlooked is the behavior of materials under extreme conditions, such as high temperatures or mechanical stress.

Thats where Coma Distortion Testing comes in a specialized laboratory service provided by Eurolab that helps businesses understand how their materials will react to various environmental factors. In this article, well delve into the world of Coma Distortion Testing and explore its importance for companies seeking to optimize their products and processes.

What is Coma Distortion Testing?

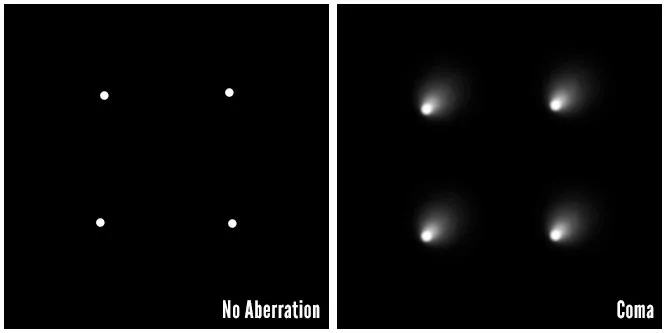

Coma Distortion Testing, also known as thermal distortion testing or heat distortion testing, is a laboratory service that evaluates how materials warp or distort when subjected to high temperatures. This type of testing is essential in various industries where materials are exposed to extreme temperatures during production, use, or storage.

The primary goal of Coma Distortion Testing is to determine the temperature at which a material undergoes significant distortion or warping, known as the coma point. By identifying this critical threshold, businesses can take steps to prevent damage, improve product quality, and reduce costs associated with material defects.

Advantages of Using Coma Distortion Testing

The benefits of Coma Distortion Testing are numerous, making it an indispensable tool for companies in various sectors. Here are the key advantages

Improved Product Quality By understanding how materials behave under extreme temperatures, businesses can design products that meet or exceed performance expectations.

Reduced Material Defects Identifying potential material issues before production enables companies to take corrective action, saving time and resources.

Enhanced Safety Coma Distortion Testing helps businesses ensure their products are safe for use in various environments, reducing the risk of accidents or injuries.

Increased Efficiency By optimizing materials selection and processing conditions, companies can streamline their manufacturing processes and reduce production costs.

Competitive Advantage Companies that utilize Coma Distortion Testing demonstrate a commitment to quality and innovation, setting them apart from competitors.

How Does Coma Distortion Testing Work?

Eurolabs Coma Distortion Testing service involves the following steps

Sample Preparation Materials are carefully prepared for testing by cutting or machining them into standard samples.

Thermal Exposure Samples are subjected to controlled temperatures, typically using specialized equipment such as a heat transfer oven or a thermocouple.

Distortion Measurement The warpage or distortion of each sample is measured and recorded at regular intervals.

Data Analysis Results are analyzed to determine the temperature at which significant distortion occurs (coma point).

Reporting and Recommendations A comprehensive report outlining test results, conclusions, and recommendations for material selection and processing conditions is provided.

QA Your Questions Answered

Weve addressed some common questions about Coma Distortion Testing below

Q What types of materials can be tested using Coma Distortion Testing?

A Eurolabs service is suitable for a wide range of materials, including metals (aluminum, steel, copper), polymers (plastics, resins), and composites.

Q Can I use my own equipment or testing methods?

A While we appreciate your interest in self-testing, our advanced equipment and expertise ensure accurate and reliable results. Our recommended procedures have been validated through rigorous quality control measures.

Q How long does a Coma Distortion Testing project typically take?

A Project duration varies depending on the scope of work, material complexity, and testing requirements. Well provide a customized timeline for each project.

Q Are test samples returned to me after completion?

A Yes, your original samples will be returned in their entirety, along with detailed documentation and recommendations.

Conclusion

Coma Distortion Testing is an indispensable tool for businesses seeking to optimize material performance and quality. By partnering with Eurolab, companies can benefit from expert analysis, state-of-the-art equipment, and customized reporting. Dont let material defects hold you back choose the reliable, precision-driven service of Coma Distortion Testing from Eurolab today.

Learn More About Our Coma Distortion Testing Service

If youre interested in learning more about our laboratory services or would like to discuss a specific project, please dont hesitate to contact us. We look forward to helping you unlock the full potential of your materials with Coma Distortion Testing from Eurolab.