Unlocking the Secrets of Abrasion Pattern Imaging Revolutionizing Materials Testing with Eurolab

In todays fast-paced manufacturing industry, understanding the behavior and performance of materials is crucial for businesses to stay ahead of the competition. With the increasing demand for high-quality products, companies are continually seeking innovative methods to analyze and evaluate the properties of various materials. Among these cutting-edge techniques is Abrasion pattern imaging, a laboratory service provided by Eurolab that has been gaining popularity in recent years.

What is Abrasion Pattern Imaging?

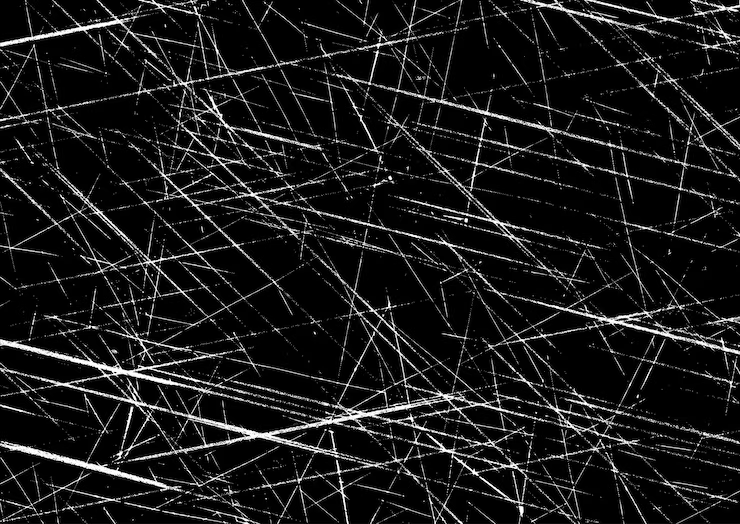

Abrasion pattern imaging (API) is an advanced laboratory testing method used to determine the wear resistance and durability of materials. This non-destructive technique involves subjecting samples to controlled abrasion forces, which creates characteristic patterns on their surface. By analyzing these patterns using specialized software and equipment, API provides valuable insights into a materials ability to withstand mechanical stress, scratches, and erosion.

Why is Abrasion Pattern Imaging Essential for Businesses?

API has become an essential tool in the manufacturing industry due to its numerous benefits. Here are just a few reasons why businesses should consider incorporating API into their testing protocols

Key Benefits of Abrasion Pattern Imaging

Accurate Material Selection With API, companies can confidently select materials with the optimal wear resistance and durability for specific applications, reducing the risk of material failure and associated costs.

Improved Product Reliability By understanding a materials abrasion patterns, businesses can identify potential issues early on and develop targeted solutions to enhance product performance and lifespan.

Enhanced Quality Control API enables manufacturers to monitor the quality of their materials in real-time, ensuring that products meet stringent standards and regulations.

Cost Savings By optimizing material selection and usage, companies can reduce waste, minimize production downtime, and lower overall costs associated with material failure.

Increased Efficiency With APIs quick turnaround times and non-destructive testing capabilities, businesses can accelerate their product development cycles and get to market faster.

Compliance and Certification API results provide a solid foundation for meeting regulatory requirements and obtaining necessary certifications, such as ISO 9001 and ISO/TS

How Does Abrasion Pattern Imaging Work?

The API process involves the following steps

Sample preparation Eurolabs experienced technicians carefully prepare samples according to client specifications.

Abrasion testing Samples are subjected to controlled abrasion forces using specialized equipment, creating characteristic patterns on their surface.

Imaging and analysis High-resolution images of the abrasion patterns are captured and analyzed using advanced software to determine material properties.

QA Section

Frequently Asked Questions about Abrasion Pattern Imaging with Eurolab

Q What types of materials can be tested using API?

A Eurolabs API service is suitable for a wide range of materials, including metals, polymers, ceramics, and composites.

Q How long does the testing process take?

A Our state-of-the-art equipment and experienced technicians ensure quick turnaround times, typically within 24-48 hours.

Q Is API a destructive testing method?

A No, API is a non-destructive technique that allows samples to be reused for further analysis or other testing protocols.

Q Can I obtain certification for my products using API results?

A Yes, Eurolabs API reports can serve as the basis for obtaining necessary certifications and meeting regulatory requirements.

Q How do I get started with Abrasion Pattern Imaging at Eurolab?

A Simply contact us to discuss your testing needs and schedule a project with our expert team.

Conclusion

Abrasion pattern imaging is an indispensable tool in todays manufacturing landscape, offering businesses unparalleled insights into material properties and performance. By leveraging API, companies can optimize their product development cycles, reduce costs, and ensure compliance with regulatory standards. With Eurolabs expertise and cutting-edge facilities, you can trust that your Abrasion Pattern Imaging needs are met with the highest level of precision and reliability. Contact us today to discover how API can revolutionize your materials testing protocols!